Blow molding is a neat way to make plastic bottles and other hollow containers. It is almost like blowing up a balloon but with plastic. This is what eceng four cavity blow moulding machine is very good at. It can produce four bottles at a time, which is great if you need to make a lot of bottles in a hurry. Let’s take a deep-dive into how this machine operates and just what it does well for businesses that require a high demand of plastic bottles.

Eceng’s machine is super fast: It can produce four bottles simultaneously. Picture having not one magic wand but four, and you’ve got the idea for how this machine works. It’s almost like getting away with being four people instead of just one. This speed is ideal for when companies must produce many bottles for the likes of water or soda.

Not only does the machine work fast, but it produces really nice-quality bottles. Each bottle comes out just right — and that’s something that’s important when you want your product to look nice sitting on shelves in stores. Not only is the quality better, there are less bottles thrown away because they didn’t turn out quite right, which saves money and is better for our planet.

Bottle-making is expensive but Eceng’s machine saves on costs. Since it operates so quickly and produces high-quality bottles, companies haven’t had to invest as much in production. Which means they can make more bottles without having to invest a ton of extra cash.

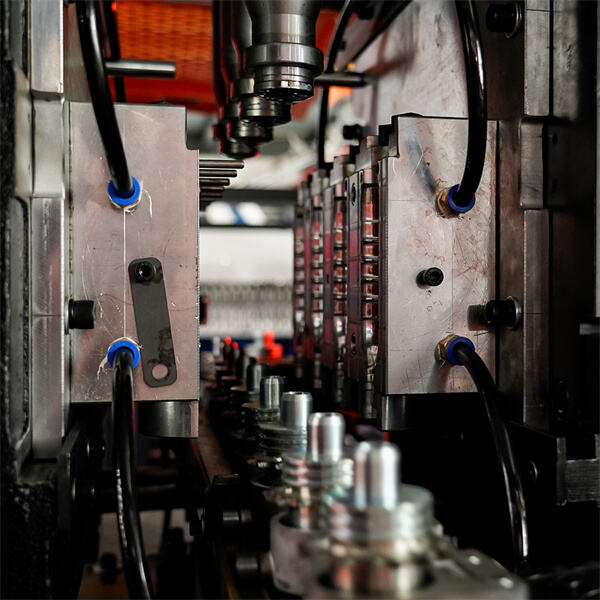

This machine features some very clever tech to ensure each of them is e made in topnotch style. It’s sort of like having a very, very smart robot that ensures everything goes perfectly every time. This is a win for businesses because they’re able to consistently rely on the bottles being a perfect fit.

What’s also cool is that Eceng’s machine can be reconfigured to make a variety of different bottles. So if a company requires a special size or shape, the machine can be configured to produce exactly what they need. This makes it incredibly versatile for all sorts of products.