Managing humidity in PET blowing machines production is really important. If humidity get too high or too low, it cause many problems that hurt the product quality. Eceng know well how to control this right humidity. This make machines run smooth and...

VIEW MORE

When thinking about servo-driven 4 cavity machine, a lot of buyers ask themself how much money they can get back from the investment. This thing called ROI, return on investment. It help you see if buying that machine is really worth it or not. ...

VIEW MORE

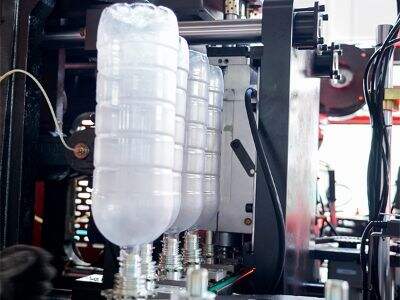

High-speed PET blow molding is fast way to produce plastic bottles efficient. But it make alot of waste and scrap sometime. At Eceng, we understand how important reduce this waste because it save money and good for environment too. In this article, w...

VIEW MORE

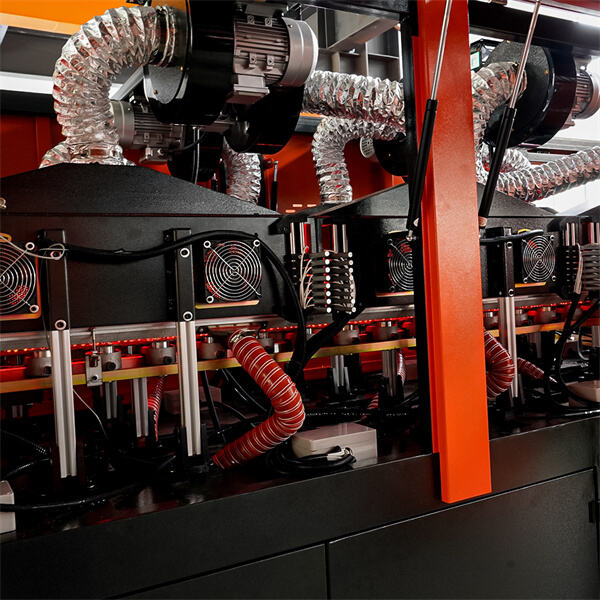

Electric technology have changed lots of industries, and one of coolest part is machines for making plastic bottles, you know PET blowing machines. These equipments are really key for produce bottles that hold drinks, shampoos and some other liquids....

VIEW MORE

Reducing energy costs in industrial pet blow molding is smart move for any company. At Eceng, we know how important save money while keep production go smooth. Energy take big part of budget, so find ways to cut it down is really good idea. With few ...

VIEW MORE

By maximizing your fully-automatic blow molding machine’s cycle times, you can increase your production efficiency. Common Problems That May Be Causing Your Blow Molding Cycle Time to Slow DownThere are so many things that can cause your b...

VIEW MORE

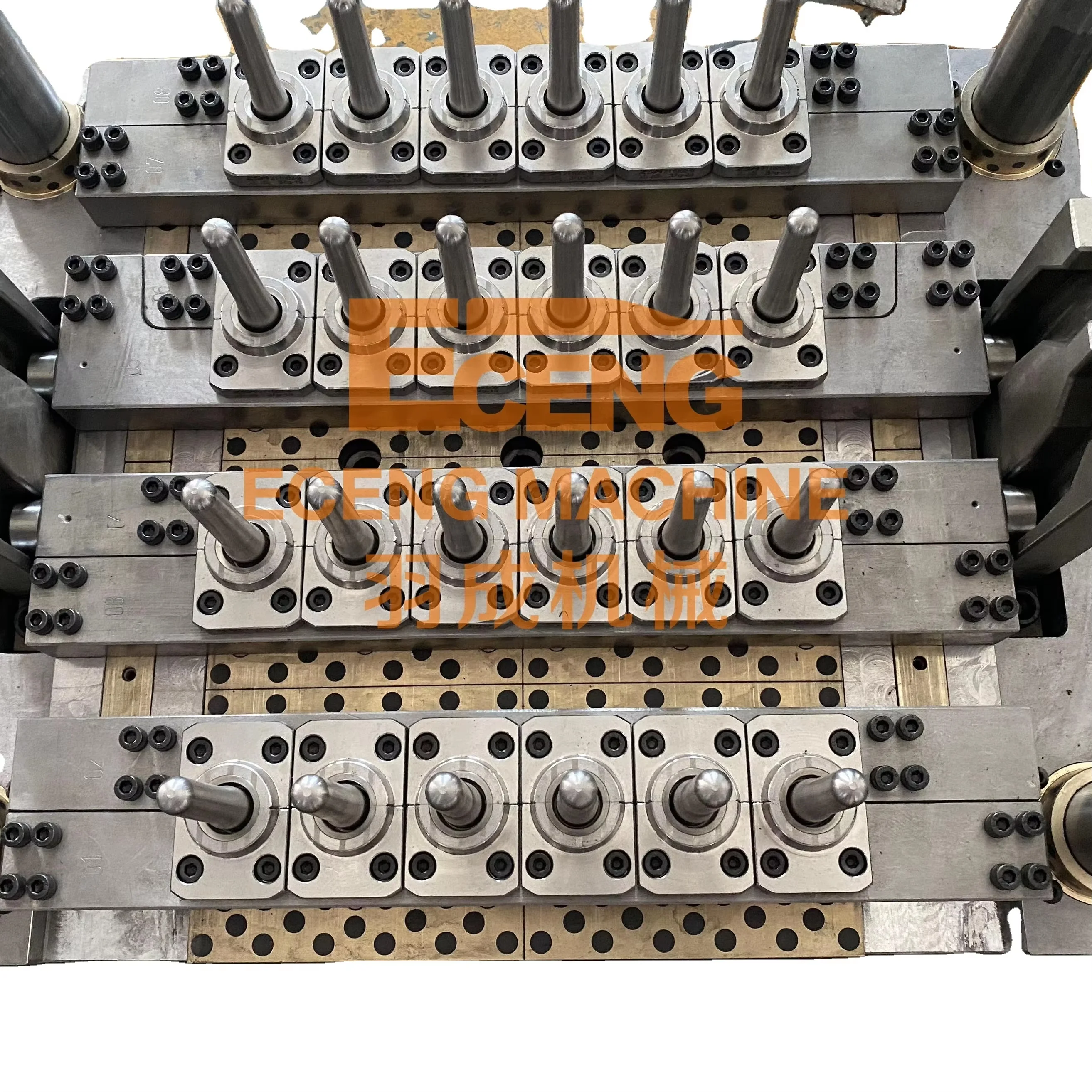

Bottle making is a crucial job in lots of factories, and the right way to make them is even more important. When it comes to accuracy with bottle forming, stretch rods are significant. A stretch rod forms the bottle as it is made. Get the sheave...

VIEW MORE

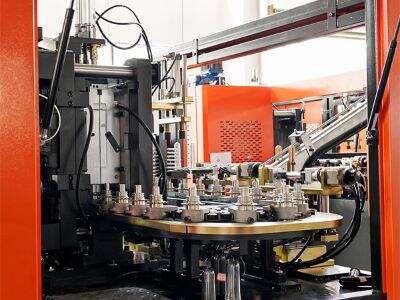

A step of introducing the pet blowing machine into a liquid filling line is important for companies who fill bottles with beverages or other liquids. The Right Machines Working Together Here at Eceng, we understand how important it is to have the cor...

VIEW MORE

There are often countless problems for small beverage brands, especially at the beginning. The best decision they can enter into is investing in a 4 cavity machine supplied by Ecoeng. This machine can enable them to churn out a greater volume of drin...

VIEW MORE

It’s really important that we use less, a lot less material when we do start of the PET blow molding process. I think that when we start really making, there’s a fair amount of waste. This is how robots get assembled or new designs tested. At Eceng, ...

VIEW MORE

For Consistent PET Bottles Profile MeasurementOur state-of-the-art equipment means that all PET bottles are produced to the same high standard. Using the latest technology and engineering we do not compromise on quality which is why every bottle will...

VIEW MORE

Find the Advantages of Using a 2-Cavity PET Blowing Machine for Wholesale ProductionWe get the need for efficiency and precision in your production process at Eceng. This is why our 2-Cavity PET blowing machine is used by industry leaders -- for bulk...

VIEW MORE