Eceng 5 gallon PET blow molding machine is one of our key products. It's important for you as someone involved in the manufacturing business to understand how this machine operates. We will discuss the technology behind PET 5 gallon blow molding machine, the bottle production process one step at a time with a 5-gallon PET machine, why precise heating and cooling matter during the molding process, what automation features are utilized to increase efficiency, and how to maintain your machine so that it's performing at its best

PET blow molding technology introduction

PET blow moulding technology is the most common technology utilized for the production of plastic bottles. PET (polyethylene terephthalate) is a form of thermoplastic polymer and is used for packaging liquids. The PET material is heated to melting, and then air is blown into a mold to give the bottle its shape. This technology makes it possible to manufacture bottles of different shapes, sizes and designs, so it is one kind of bottle blowing machine which is very flexible and is an innovation in packaging industry

How to make bottle step by step with a 5gallon pet machine

The preform is the first step in the bottle production 5 gallon PET blow molding machine. The preform is a small plastic tube that is heated to form the bottle shape. Then, the preform is fed into the machine where it is heated and inflated with compressed air forms as the bottle which is intended. The bottle is then shaped, cooled and ejected from the machine. The machinery is completely automated and is run by state of the art computers controlling the process to avoid any variation of the product in each bottle

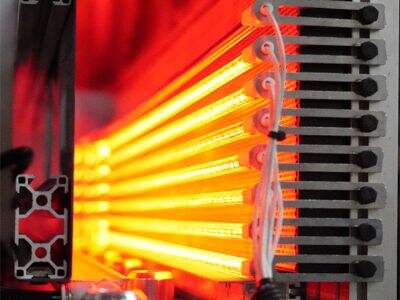

The purpose of proper heating and cooling in mould processing

Accurate heating and cooling is the most important part of the molding cycle in a PET 5 gallon blowing machine. The PET must be heated to the melting point for shaping. If it is too cold, the material may not flow properly, producing faulty bottles. Otherwise, when the temperature is too high, the material could be deteriorated, resulting in bad bottles. Cooling the blow molded bottles properly at correct temperature is also important to avoid distortion and to make the finished product in compliance with quality

Automated functions for more efficiency and consistency in production

The automated functions largely increase the efficiency and consistency of the bottle production from 5 gallon PET machine. Such machines have sophisticated sensors and control systems which control the temperature, pressure, timing, etc. of the molding process. This is to ensure each bottle manufactured to the standard required with as little human interference as possible. Furthermore, automation can minimize the likelihood of mistakes and speed up the production process, which is an asset thoroughly worthwhile for manufacturers, such as Eceng

Maintenance of the machine for best performance and long life

Regular maintenance is crucial to realize the best performance and the longest life of the PET blow 5 gallon bottle blowing machine. For the latter, comprehensive maintenance involves cleaning the equipment frequently to get rid of any fragment or remnants that may interfere with plastics molding. There is also key maintenance between lubricating moving parts, checking electrical components, and replacing worn parts to avoid breakdowns and keep running smooth is required. By adhering to such routine maintenance, oems can ensure that 5-gallon pet machine work optimally and longer, which will eventually save time and money

A 5-Gallon PET Blow Molding Machine — Knowing How the Bottle is Produced Is Critical For Those Who Work In The Industry For manufacturers in the industry, it’s important to know how a 5-gallon PET blow molding machine works-form bottle production. Eceng's technology and automatization level makes it efficient, constant and reliable to manufacture top quality plastic bottles with their machines. By putting exact heating and cooling first, and performing regular maintenance, a manufacturer can go from reacting to issues to a state of proactive ease in maintaining equipment that performs. While the need for this type of plastic bottle has never been higher, those that have great PET blow molding machines at their disposal, like the ones available from Eceng, are going to have a big advantage over the competition.