Why Preform Heating is Important

Preform heating is an important procedure in the manufacture of PET bottles. This process heats the preforms, little tubes of plastic that will be blown into shape to make the final bottle. Heating the preforms to a certain temperature is very important for final quality of transferred product. The preform heating is so well controlled distributed that plastic distribution with no thin wall, and off-centered bottom are reduced. Appropriate heating of the right preform can also increase bottle clarity, strength and possible consumer appeal.

Why Preform Heating is Important in The Manufacture of PET Bottles

Preform-heating is a critical stage during the manufacture of PET bottles, as it directly affects the quality of the final bottle. Incorrect preform heating leads to defects like bubbles, deformation or uneven wall thickness causing impaired appearance and safety of the bottle. By heating the preforms correctly and evenly, there achieved bottle shapes that are aesthetically pleasing but are also sturdy and serviceable. Furthermore, appropriate preform heating can reduce production expense by reducing scrap and increasing good bottles per preform mass.

Recommendations on The Preform Heating in Pet-Bottle Production

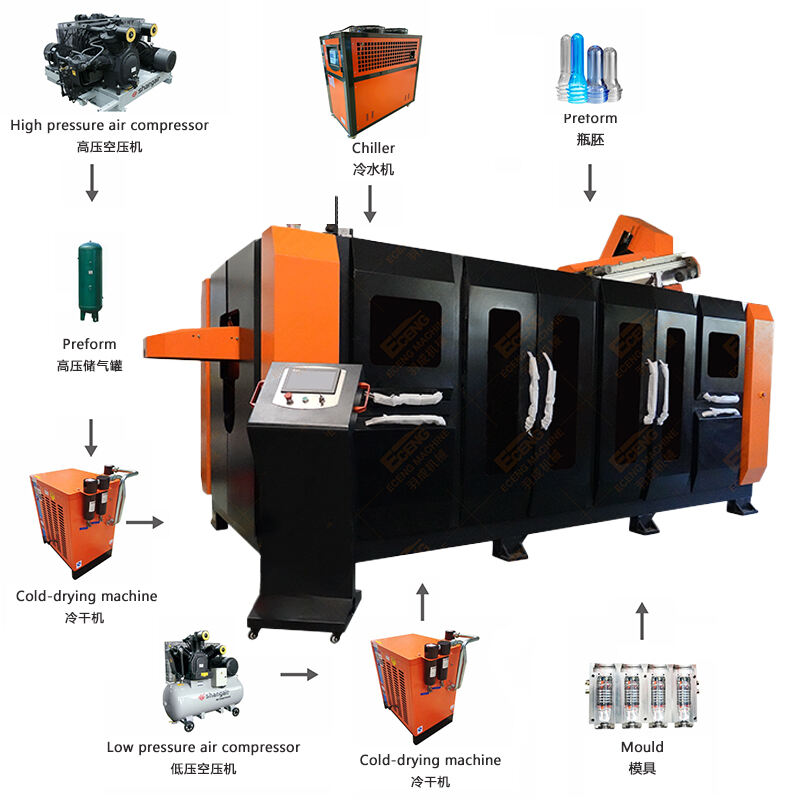

In the case of preform heating in PET fully automatic plastic bottle making machine production - there are several best practices that manufacturers can consider to maximize end product quality. High quality preforms heating equipment operating both consistently and in temperature emerged as our first requirement. This will also tend to make the preforms heat up uniformly and it will be less likely that defects appear in the final product. Furthermore, manufacturers need to be very careful of the heating time and temperature because either overheating or under heating will cause defects in preforms. Preform heating equipment require regular maintenance and calibration to ensure accuracy, consistency, as well as high operational efficiency.

Learn the Benefits of Good Preform Heating

A number of advantages are attained for plastic bottle manufacturing equipment when the preform is heated optimally. It is for this reason that it makes sense to invest in the very best preform heating equipment so that manufacturers can enhance their product quality, increase customer satisfaction and brand reputation. At the same time, and in addition to improving bottle properties, good preform heating is a means to maximize production efficiency by lowering defect rates and waste generation. Finally, the benefits of preforms heating well go far beyond production and such a performance is likely to be reflected in the business results of a manufacturing site throughout the years to come.

Top 7 Places to Find Best Preform Heating Machine for PET Bottle Production

Zhangjiagang Eceng Machinery Co., Ltd is the professional – PET Bottle Blowing Machine manufacturer and suppliers in China. Being an experienced and qualified supplier in the industry, Eceng has been supplying different equipment to valued customers for over 20 years. Eceng provides comprehensive preform heating solutions with state-of-the-art delivery technology at your disposal. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in food & beverage and other industries. Through partnership with Eceng, manufacturers are able to take advantage of the latest in technology and expertise for a perfect preform heating process and top-quality PET bottle production.