Electric Stretch Blow Molding Machine User Friendly 6 Cavity K6

| Model Eceng K6 |

|

Bottle type specification

|

Cavity |

6 |

| Max.volume |

200ml-2000ml |

| Bottle mouth maximum overall diameter |

25-29mm NECK |

| Bottle biggest diameter |

100mm |

| Bottle maximum height |

330mm |

|

Capacity specification

|

Theory output |

12000-14000BPH |

| Bottle type volume |

600ML |

| Bottle type weight |

13.5g |

| Bottle type |

Round |

| Power specification |

Light tube quantity |

32pcs |

| Light tube power |

1.25KW |

| Maximum heating power |

40KW |

| All electric machine installation |

49KW |

| Actual consumption |

30%--60% |

|

Air pressure specification

|

Work pressure |

5-6kg/cm2 |

| Blow bottle pressure |

25-45kg/cm2 |

| Higher -pressure gas consumption |

8000Ltr/min |

| Forzen water specification |

Work pressure |

5-6 kg/cm2 |

| Temperature range |

10℃ |

| Consumption |

8000kcal/hr |

| Forzen water flow |

120L/min |

| Machine specification |

Machine size |

5.5x1.8x1.9 |

| Machine weight |

6.1ton |

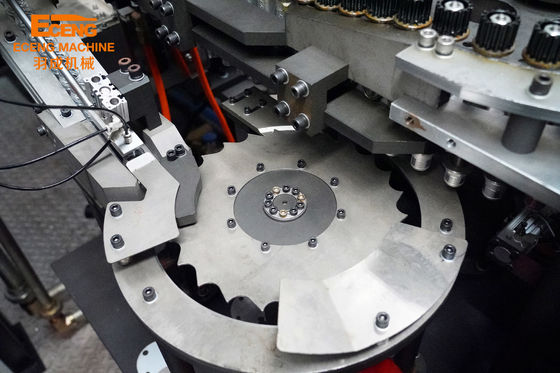

Are you in search of an electric stretch blow molding machine that combines efficiency and user-friendliness? Look no further than our K6 model, equipped with 6 cavities and capable of high-speed production, reaching up to 14,000 bottles per hour!

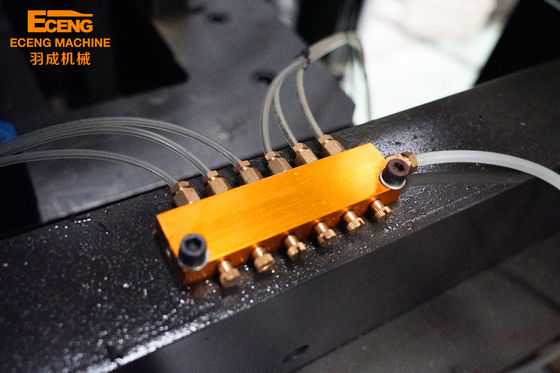

Designed with an intuitive user interface and advanced control system, the K6 electric stretch blow molding machine guarantees precision and speed without any complications. Whether you manufacture beverage bottles, personal care products, or other plastic containers, the K6 ensures consistent, top-quality results with every production run.

Its compact and modular design makes installation and maintenance a breeze, making it an ideal choice for production facilities of all sizes. Don't settle for anything less than the best—choose the K6 electric stretch blow molding machine and elevate your performance, reliability, and ease of use to new heights!

Experience the pinnacle of efficiency and craftsmanship by investing in our K6 electric stretch blow molding machine. Join countless satisfied customers who have trusted us for their bottle production needs. Don't miss out on this opportunity to take your business to the next level. Contact us today!

K linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

Kseries linear bottle blowing machine features:

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control, simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle .

Zhangjiagang Eceng Machinery Co., Ltd is founded in 2007,We manufacture fully-automatic PET bottle blowing machine, injection mold,blowing mold etc.,suitable for 5ml-50L plastic bottles,water bottles,carbonated beverage bottles,oil bottles,cosmetics bottles.We can equip machine from 1-12 cavity,output from hundreds bottles to 36,000 bottles/hour,also provide full set of production system from preform production,bottle blowing,filling to final packaging.

So far Eceng machinery have provided more than 2050 sets machines for more than 170 countries in the world.Our equipments are highly estimated by the clients, and are well known at home and abroad.We sincerely hope to establish business relationship with friends all over the world.

Our Services

1.Installation,debug

We will arrange seasoned technician for debug and test production at the same time make the equipment reach the rated producing capacity of the line.

2.Training

Eceng offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. After training, thetechnician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3.Quality guarantee

We promise that our goods quality, specification and function all meet the demand of contract. One year warranty,during warranty period,All parts and components exceptthose damaged by non-human factors are quaranteed free of charge (vulnerable parts are not included). In addition, the seller provides free spare parts and accessories for shipment with the machine.

During warranty period ,the equipment is damaged due to incorrect operation by thebuyer,we provide maintenance solutions,the buyer will cover the loss and cost.during warranty period we provide technical service,which is usually solved by telephone,etc.if not,provide door-to-door service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!