- Technical Parameter

- Machine details

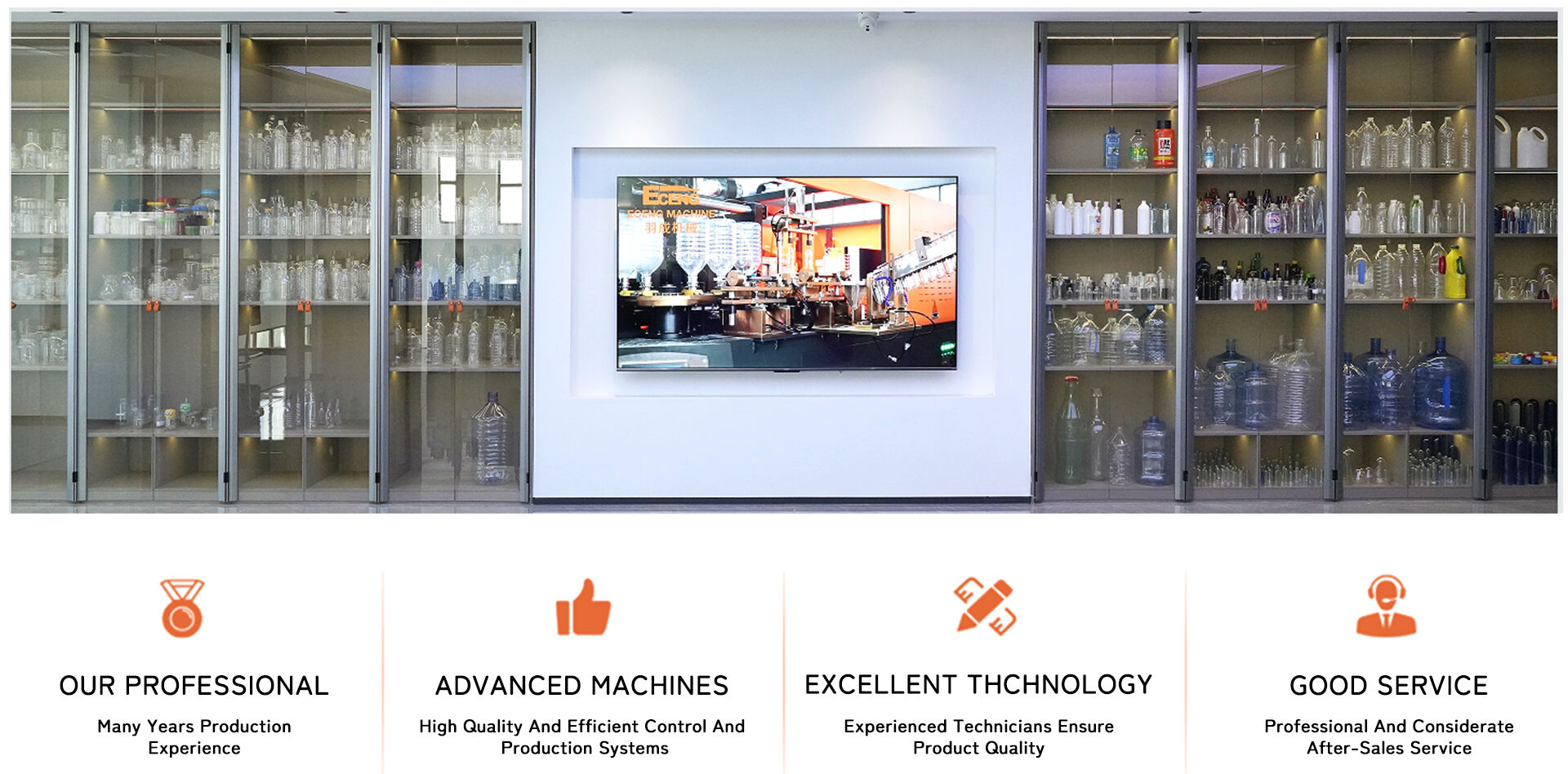

- About us

- Sample Room

- Eceng Machinery Service

- Video

- Recommended Products

| Model | YC-10L-1 | |

| Product Spec | Cavities | 1 |

| Max.volume | 10L | |

| Theory output | 200-250BPH | |

| Max. preform neck size (mm) | 180 | |

| Max. product diameter (mm) | 300 | |

| Max. product height (mm) | 480 | |

| Blow molding part | Die stroke (mm) | 340 |

| Max. mould size (mm) | 380×450 | |

| Mould thickness | Adjustable | |

| Mould spacing (mm) | Adjustable | |

| Max. pulling stroke (mm) | 500 | |

| Machine size (L×W×H)(m) | 2.3×0.77×1.96 | |

| Machine weight (KG) | 1000 | |

| Oven | Total power (KW) | 15-40 |

| Oven Size (L×W×H) | 2.37×0.68×1.65 | |

| Oven weight (KG) | 380 | |

-

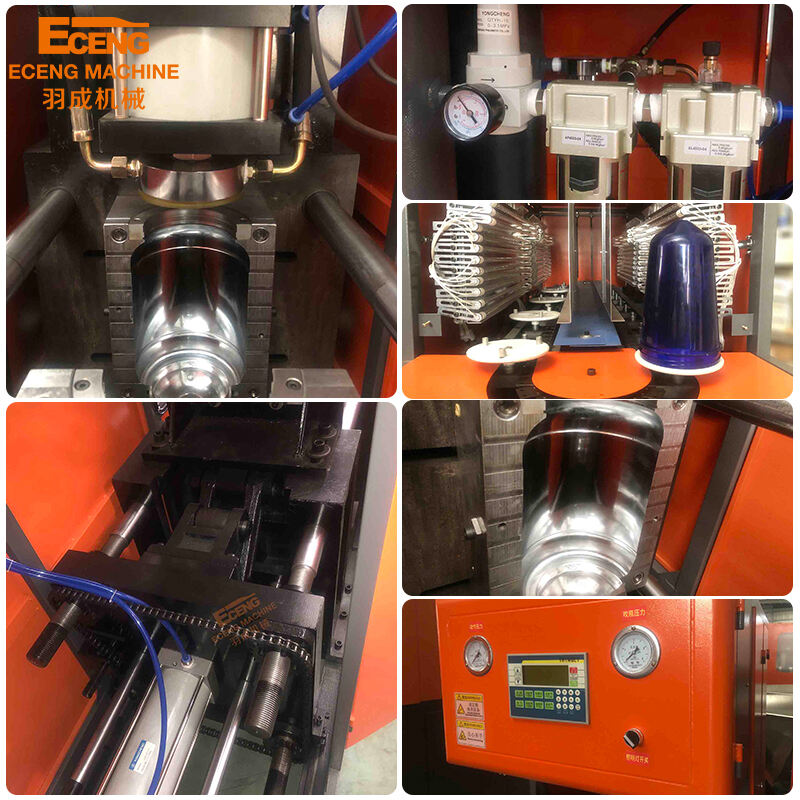

High flexibility

Small size, low investment, easy and safe operation

-

Touch screen

Easy to set the parameters of the machine

-

Mold closing system

Front-opening design, Easier to get the bottle

-

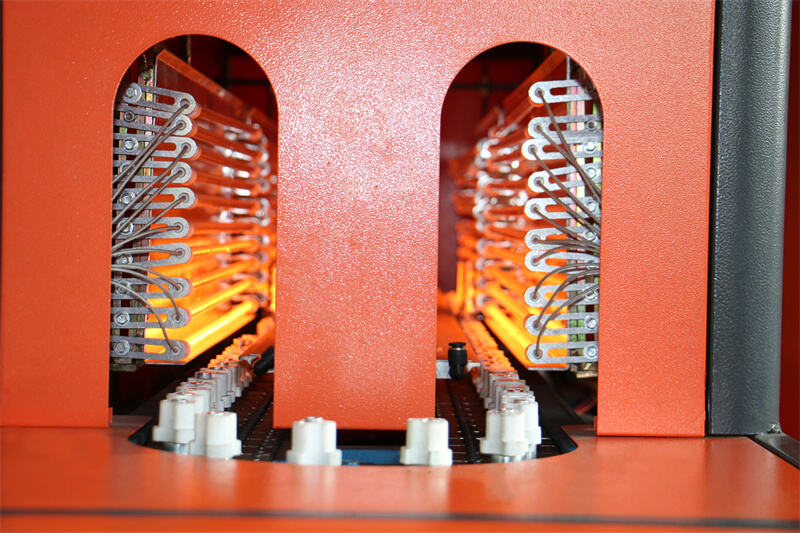

Heating system

High-temperature lamp heating, Fast and thorough

-

High-pressure air system

Quality brands, high capacity, quick response

-

Blowing system

Clear, flawless, High quality bottles.

What Can Blow with Eceng Bottle Blowing Machine

including but not limited to:

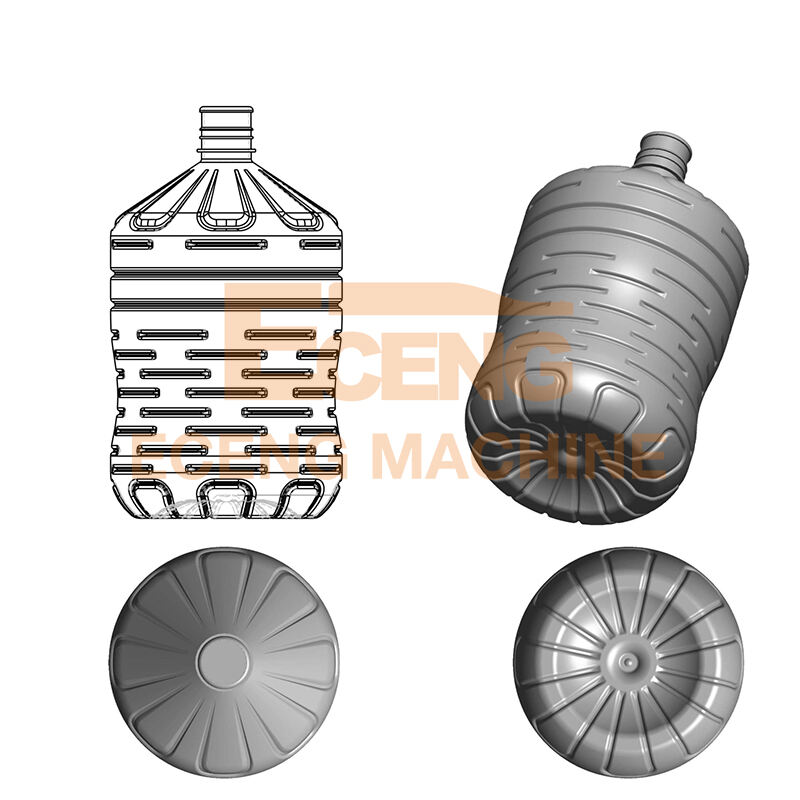

Round Bottles: commonly used for water bottles, juice bottles, soda bottles, etc.

Square Bottles: commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

Oval Bottles: commonly used for personal care products such as cosmetics, body washes, shampoos, etc.

Irregular-Shaped Bottles: such as flat bottles, triangular bottles, hexagonal bottles, etc.

We can make the most suitableconfiguration according to your requirement in you new project.

-

Bottle Design.

Our designers can design bottle styles according to your requirements.

-

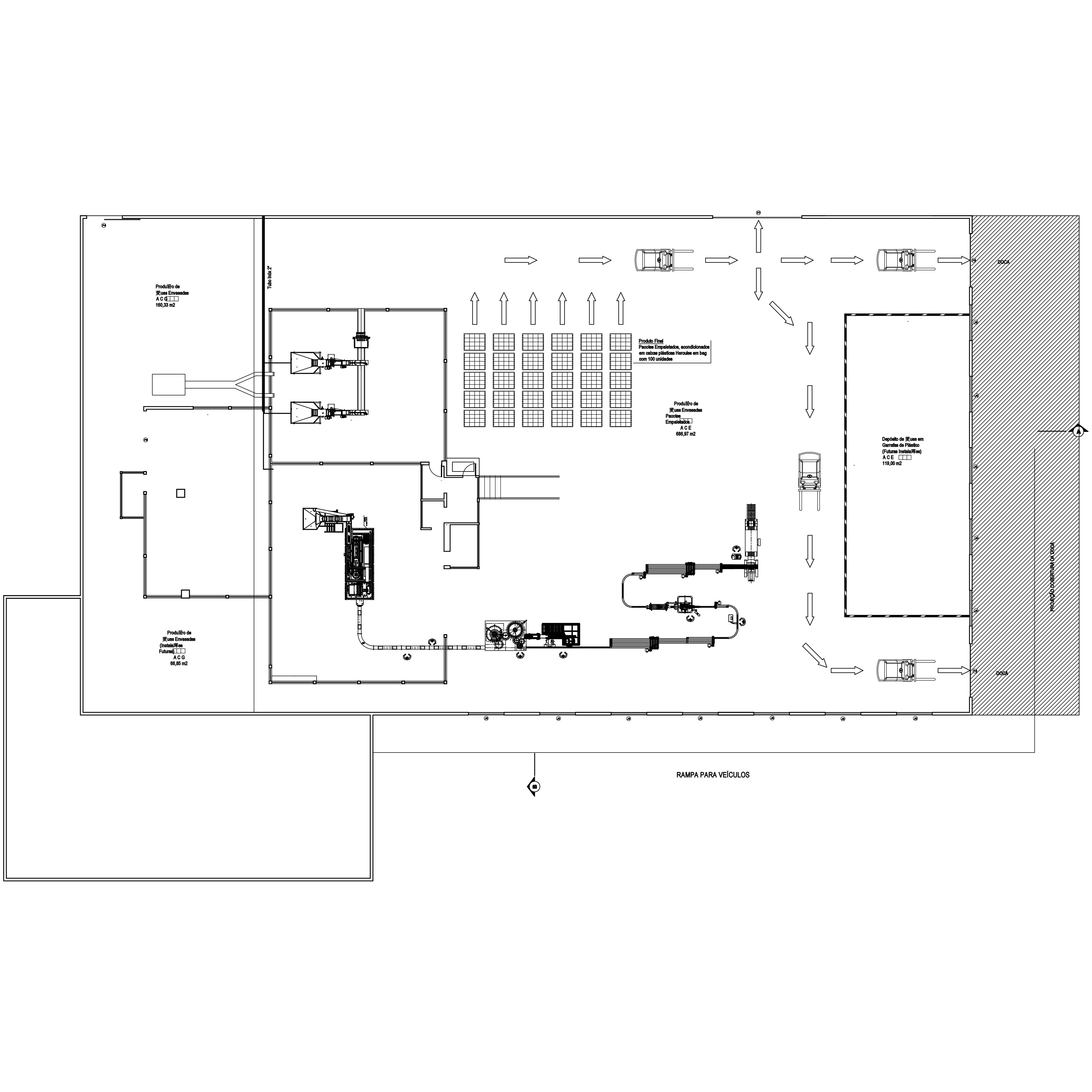

Machine Layout.

We will confirm the machine layout according to your factory.

-

Sample Project.

We can provide a sample project for you to visit.