For the bottle blow molding machines, Eceng is a name to be reckoned with as they ensure that their product quality can match up to the demand of wholesale clients. Precision engineered and beautifully crafted with every detail carefully considered, our machines have been constructed to meet the most strenuous specifications for safety and performance. No matter you are a small business or big enterprise, Eceng have the right solution for you. We collaborate with our clients to understand their needs, and tailor make packages or build turnkey solutions that will optimise processes and create a simplified operation. Whether you need easy maintenance, flexibility or efficient energy utilization, we have the perfect bottle molding machine solution for you from Eceng!

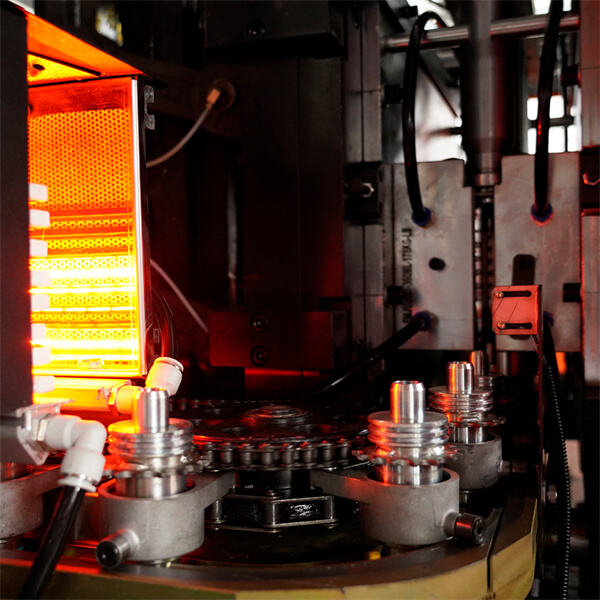

With the bottle mould blow molding machine of Eceng Machine, buyers can benefit from a compact and versatile production tool that serves the needs of modern manufacturing. Our devices are fitted with automation and digital transformation capabilities that drive productivity and ease of work. Eceng, adopting a market-oriented and customer-driven management philosophy, has developed into a high-technology enterprise with more than 15 years of professional level in extrusion blow molding machine. That leads us to availability for offering services after have been enable to produce the molding machine up on the international advanced technology in quality, speed, energy-saving, ease for operation, automaticity, freedom from contamination, long life span and easy maintenance. From lean manufacturing techniques to smart factory facility, Eceng is leading the pack in bottle manufacturing. Our machines are always developed new by R&D work done here and therefore our presses are being constantly updated to customer requirements. Whether you want to create more production, better efficiency, lower lead time or stand up to the competition, Eceng systems can help you.

If you are in the market for a bottle blow molding machine, there are a few things to look at to make sure you know that you have picked the right one for what you do. The first thing is you have to decide what sort of bottle (in term of shape, size and production capacity) are you making as these molding machines are made for specific type bottles. Check the production capacity of the equipment to make sure that it can meet your requirements. Also choose models that are simple to use and clean, so you can reduce your downtime and increase your performance. The quality and stability of the machine are also taken into account for continuous production of high-quality bottles.

Although bottle blow molding machines are known to take into account the movement of slots with bottles, they may run into common problems which reduce work efficiency. One problem that arises often is wear on molds, leading to inconsistent bottle sizes and shapes. To avoid the problem, the moulds should be checked and maintained on a regular basis. Air leaks are another frequent problem which can also affect the quality of bottles made. Be sure to inspect for air leaks often and replace worn parts. Size variations also have inconsistent bottle-thickness due to control of temperature. It is important to track and adjust temperature settings to assure the repeatable bottle quality.

If you want the best bottle blow molding machine manufacturers for the machines ensure high quality and stellar performance, then Eceng is what to look. Eceng offers a varieties of bottle blow molding machine to suit different production demands. Their equipment ranges from durable, efficient and easy to use conveyors that are the perfect solution for moving a variety of materials; conveyors that will be an ideal addition to any manufacturing or warehouse operation. Offering reliable high-quality bottle production via Eceng systems means customers are always satisfied deciding to go with an Eceng machine. Opt for Eceng and get the best bottle blow molding machines performance you can rely on.