Stretch blow molding machines are truly a wonderful means that is save of bottles and containers. These machines are used to make many of the plastic bottles you see in stores. Let's explore how these impressive machines operate, and why they are so crucial!

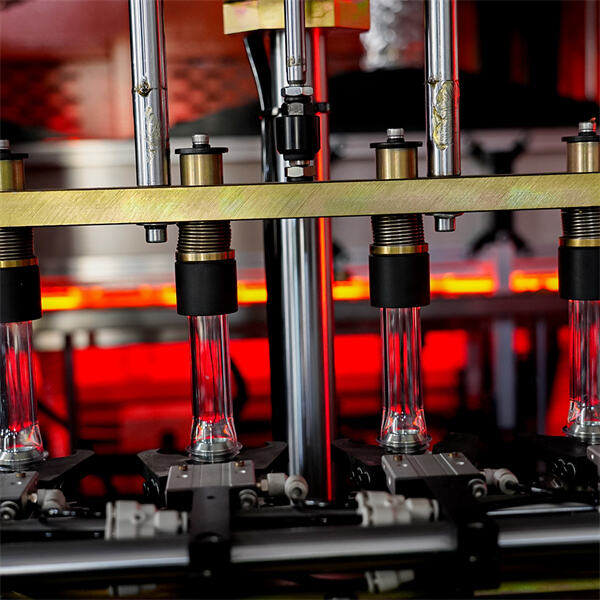

Stretch blow molding machines are unique machines that provide heat to mould the plastic into diverse forms. They operate by heating a tube of plastic material to soften it. Air is then blown into the tube to expand it around a mold and give it bottle shape. Finally, the mold is allowed to cool so the plastic can set up and hold its shape.

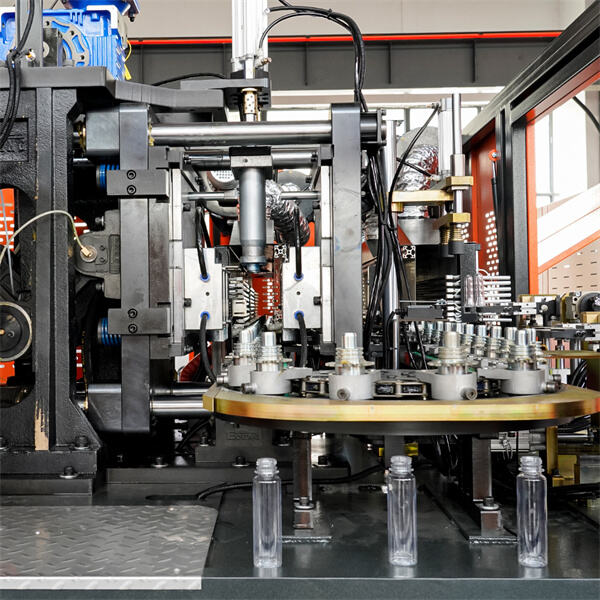

The process of manufacturing bottles and containers became faster, smoother, and easier with the advent of H3 3 Cavity 2800BPH Hand Feeding Wash Bottles Blowing Machine on to the packaging scene. In the days before these machines, bottle making was a long and painful process. Fortunately, with the introduction of stretch blow molding machines, bottles can be produced in mass quantities using an incredibly fast and efficient process that will help companies to meet demand for their products.

There are many advantages available in bottle production using Stretch blow molding machines. One of the most important feature these machines have is their ability to make bottles in different shapes and sizes, allowing companies to be diverse with their packaging designs. Moreover, to some extent, the use of a stretch blow molding machine results in lower energy consumption and cut down costs on production wastage by transforming them into fresh usable material — hence it is resource-efficient for producing bottles.

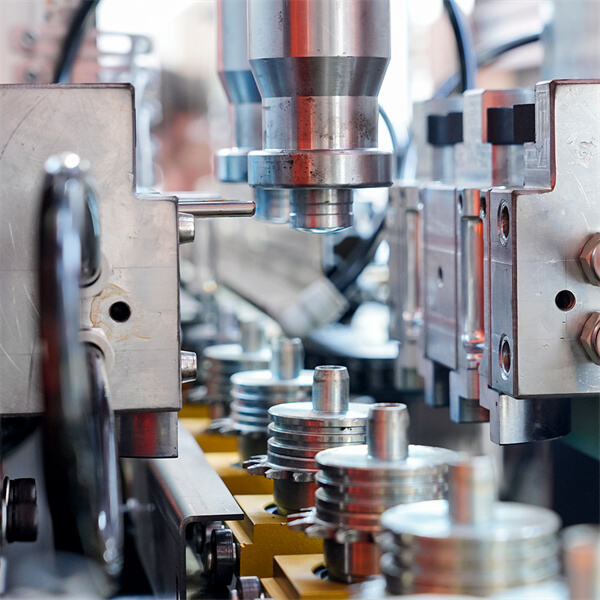

In the context of bottles produced using stretch blow molding, it is crucial to service and calibrate stretch blow molding machines properly to maintain high quality. Scheduled maintenance is a great protection to avoid anything that may distract the final product. Keeping the machines in good operation, companies can be sure that their bottles are produced effectively and meet proper qualitative standards.

Stretch blow molding machines can be divided into several categories according to the type of purpose it is meant for. For instance, some machines are more geared towards small bottles and others towards larger containers. A business must choose the best machine variant that suits their production output and the bottle size they get in return.