If you need to have some sort of equipment that will be able to manufacture corresponding type of product such as milk bottles, definitely we will suggest a kind of machine which is called H3 3 Cavity 2800BPH Hand Feeding Wash Bottles Blowing Machine. This type of machine is very useful in the dairy industry. One such company that manufactures these machines is "Eceng". Let us examine how these machines function and why they are so vital.

The milk bottle blowing machines are based on a unique technology which is of blow molding. This technology helps to mould the melted plastic into appropriate size and shape of a milk bottle. Plastic pellets are heated by the machine until it softens and then air is blown into them making them expand to resemble a bottle. The process is meticulous and is intended to ensure that every bottle is perfect.

The reason for this being the process of manufacturing milk bottles was an extremely slow and costly one prior to the milk bottle blowing machine era. Now, firms can produce many bottles quickly and much more affordably as a result of using these machines. It is as a result of this development that the dairy industry has been transformed, with companies able to manufacture more milk bottles within a short period of time in meeting the ever-rising demand for milk.

The milk bottle blowing machines are such machines which are efficient and precise. This allows them to produce hundreds of bottles at a time in just minutes, greatly increasing production. They also result in every bottle having the same dimensions as desired for the packaging of milk. This accuracy plays a critical part at saving time and money for the companies in their production line.

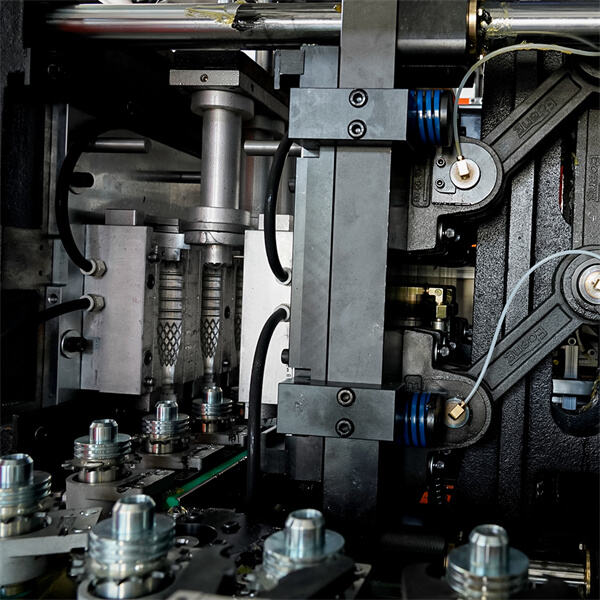

The milk bottle blowing machine is made up of many different components, all which work in a smooth process together to create bottles. This machine has three important components, a mold that simply shapes the plastic, a heater to melt the plastic pellets and blower to inject air in the molten liquid in order to blow it like a balloon. Similarly, there are sensors as well as some other controls that will ensure a smooth process. Each of these elements collaborates to make the ideal milk bottle every time.

With the increasing traffic of milk, more and more people will buy bottles for water masking. Glass blowing plant also increase so much that milk bottle blowing machines will make anybody satisfied in terms of the call for and production of bottles. With the market changing as it does, these machines enable companies to stay in touch and provide milk to customers when they need it. In this case, milk bottle blowing machine are quite needed in the dairy industry.