It’s important to have a machine that can produce H3 3 Cavity 2800BPH Hand Feeding Wash Bottles Blowing Machine plastic bottle caps with speed while performing reliably. We, Eceng Company, is able to provide one plastic bottle cap making machine that can fulfill your requirement. This machine is capable of producing high quality bottle caps fast and easy, and it is perfect for those businesses looking to scale up their outputs.

Energy Saving Reliable Plastic Bottle Cap Making Machine / Injection Molding Machine Machinery hamad 2020-1-16 Extensive Use Energy saving vertical injection molding machine Extensive Use Energy saving vertical injection molding machine FOX M30 Moulding Machine انژکتور سرد باد زنس - گروه تجهیز ماشین میادگان Efficient and Reliable...

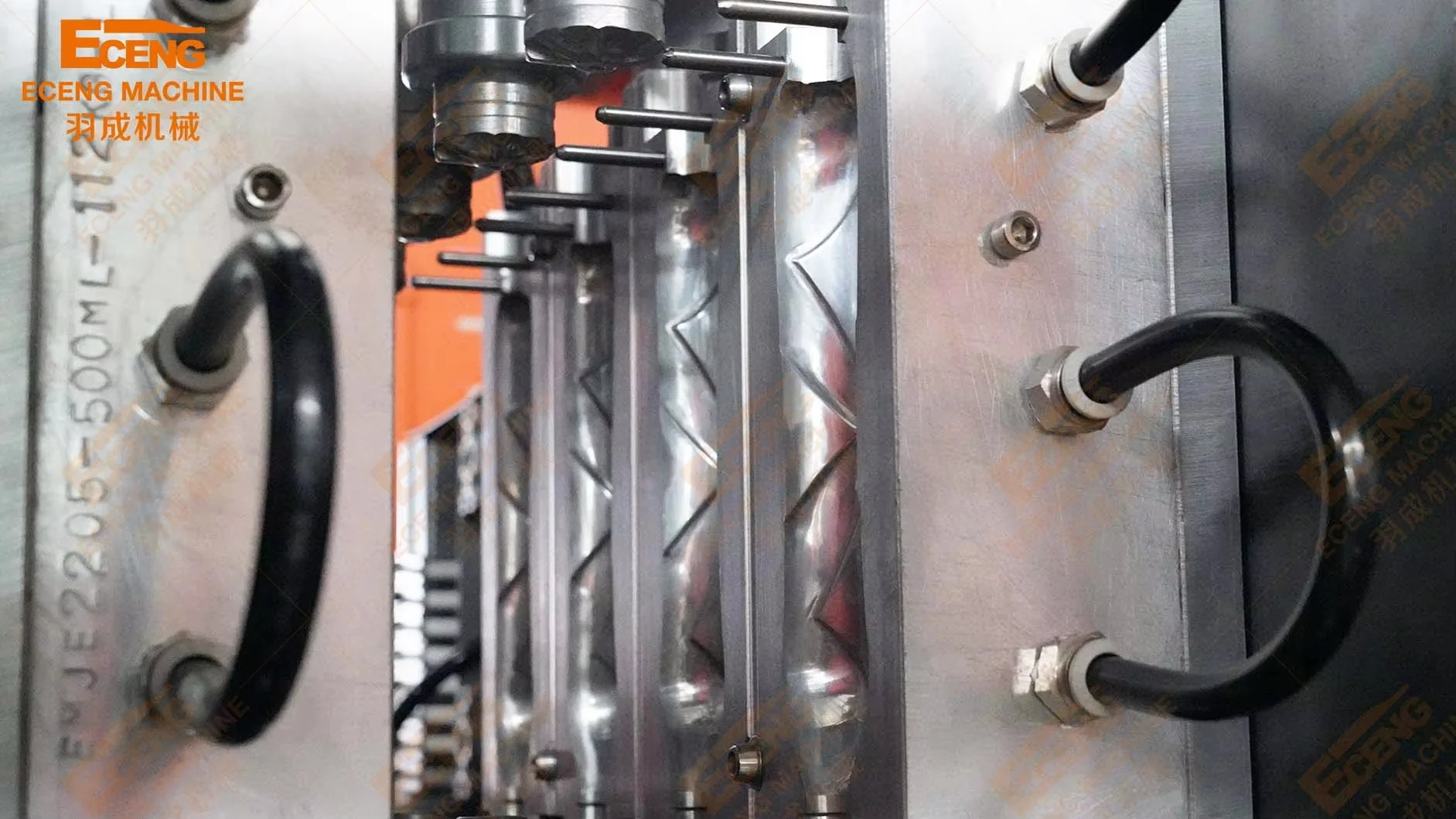

Eceng bottle cap making machine runs highly with high output, and one mold cycle can blow 1800 pc bottles. Its advanced technology ensures that each bottle cap is produced fast, yet doesn’t compromise the quality. This machine runs hours on end without issue to keep your business running when demand is high. The machine is also simple to use, so your staff can easily run it without much training.

And if you are a wholesale buyer searching for lots of high-quality plastic bottle caps, then this machine is just the one for you. It is to provide a cap that is sturdy and firmly sits on a bottle. Which means less waste -- and happier customers -- for your business. The machine is also capable of producing caps of different sizes and shapes, helping you serve different clients.

The plastic bottle cap making machine employs the latest technology to makes productivity even higher. It has unique characteristics that can help to accelerate making the cap, so more cap can be made in a shorter time. This machine also guarantees each cap is produced right the first time, decreasing the amount of rework, and the cost of you having to remake caps.

Each business is unique, and Eceng knows it. That’s why our plastic bottle cap making machine has customizable features. You get different molds and settings for different kinds of caps. That flexibility lets you use the machine for many products, which adds to the versatility of the machine in your operation.