Stretch blow moulding machines are awesome! Any kind of bottles and containers can be produced by them. We will tell you more about these incredible machines and what they do.

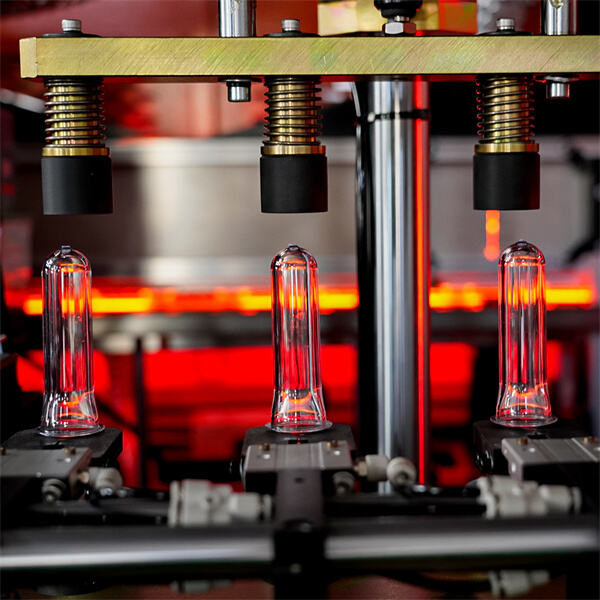

Plastic bottles and containers are made through stretch blow moulding machines. These work by melting plastic material until it is soft, then blowing air into it to take its shape in the mold. The plastic is moulded into a bottle or container shape by the mold. After the plastic has cooled and solidified, all that needs to be done is open the mould, and your part is complete!

Many advantages of stretch blow moulding machines These are quick and efficient investments that allow companies to manufacture a large number of bottles and containers in very little time. They used and even manufacture strong, durable items. Moreover, the stretch blow moulding machines are highly adaptable to manufacturing bottles and containers of every shape and size. Which makes them suitable for pretty much any industry that you can think of, ranging from food & beverage to pharmaceuticals & cosmetics.

The stretch blow moulding technology has been used in several industries in the manufacturing of different products. Stretch blow moulding machines are very common in the food & beverage industry for water, soda and juice bottles. They are used in the pharmaceutical industry to create medication and vitamin containers. Most often found in cosmetic industry as basis for bottles for lotions, shampoos, perfumes etc. The possibilities are endless!

Reusable, lightweight and cost-efficient bottles and containers have become easier to make thanks to stretch blow moulding machines. It lets companies choose packaging solutions that suit them the best and fulfill their needs. This ensures that the company stands out on shelves and is more appealing to consumers. Stretch blow moulding machines are also more eco-friendly as they produce less waste of the raw material, and consume much less electricity than traditional manufacturing.

There are some key factors that you should keep in mind while selecting a stretch blow moulding machine for your production requirements. Step 1 : First determine the size and shape of the bottles or container to be produced. Ensure your needs are capable of being made on the machine. Second, consider the machine speed and efficiency. Find a machine that is able to keep up with the number of products you need in a given time period. Last but not the list machine quality and durability. Spend money on the equipment that will last for years.