Reducing energy costs in industrial pet blow molding is smart move for any company. At Eceng, we know how important save money while keep production go smooth. Energy take big part of budget, so find ways to cut it down is really good idea. With few changes in work way, we can lower energy use and help planet also. This article talk about some effective ways to save energy in blow molding

Wholesale Solutions for Lower Energy Expenses in Plastic Manufacturing

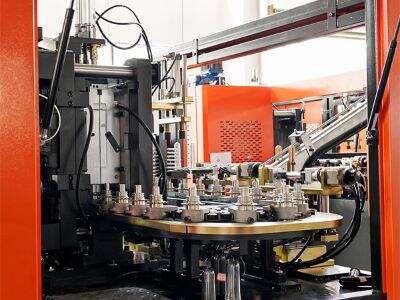

One way save energy is look for wholesale solutions. These big changes can make big impact on energy use First companies can invest in more efficient machines. Old machines usually use much more power than new one. For example switch to machine that heat plastic with less energy can cut costs a lot. Another method is optimize production process. This mean make sure machines run at best. Regular maintenance check help keep machine work good. If machine run bad, it waste energy. Training workers how use machines properly also help. When all know best way operate, it lead to less energy use. And that’s why training matter

Using smart technology another great way lower energy costs. For instance add sensors to machines can monitor energy use real time. If machine use too much power, sensor alert workers fix issue fast. This save energy and prevent expensive breakdown too. Also using energy-saving mode during off-peak hours reduce costs, because energy price often lower then. Companies can look bulk buy energy from renewable sources. This not only cut costs but also make greener environment. By combine all these strategy, companies see big drop in energy expenses

Where to Find Innovative Technologies for Energy Savings in Blow Molding

Finding right technology make big difference try save energy. There many place look for new solutions. Trade shows excellent for discover new machines and tech. Companies like Eceng often show latest advancement in blow molding there. Go to these show give insight about energy-efficient machines or methods. Online research another way find cutting-edge stuff. Websites about manufacturing and energy saving usually highlight latest innovations

Networking with other people in industry can lead to great ideas also. Join industry group or forum let companies share experience and solutions. For example if one company find new software manage energy use good, they can tell others. Collaboration bring new tech that save energy

Moreover many university and research place work on special solution for manufacturing. Partner with them bring fresh ideas and tech to company. This can include better material or advanced machine. Lastly stay update with industry magazine give valuable info about new thing in blow molding and energy efficiency. By check all these way, companies can find best technologies help cut energy costs and improve manufacturing

What Are Common Energy Wastage Issues in Pet Blow Molding

In making plastic bottles world, we use process call PET blow molding. This process sometime waste lot energy not good for environment or save money. One common problem is machines do blow molding. If not well maintained, they use more energy than should. For example if machine have worn parts, it need work harder same job which use extra electricity. Another issue heating process. Plastic must heated shape into bottles, but heat escape if machine not insulated properly. So more energy used keep plastic hot. Also some workers leave machines running even no use. This like leave light on empty room, waste energy. Finally if production schedule not plan good, machines start and stop often use extra energy. By know these common problem, companies like Eceng can make change reduce waste and save money

How to Train Staff on Energy Efficiency in Pet Blow Molding Processes

Training staff how save energy work with PET blow molding machines very important. When everyone understand be more efficient, it lead big savings. First good start with simple lesson what energy efficiency mean. Staff learn small change make big difference. For instance teach turn off machines when not use and report any machine seem use too much energy. Workshops organize where employee practice check machines make sure good order It helpful make posters remind workers energy-saving habits like turn off lights unused area. Furthermore Eceng encourage team spirit around save energy by reward employee who come great ideas. This can be recognition or small prize. Regular meetings discuss energy-saving ideas. This keep energy efficiency front mind. Training staff aware their energy use not only save money but create culture responsibility and care environment

Where to Access Resources for Energy Cost Reduction in Industrial Settings

Finding resources help reduce energy costs in industrial like PET blow molding easier than think. One best place start online. Many websites focus energy efficiency manufacturing. These site provide tips, guides, even videos show improve energy use. For example Eceng look webinars or online course teach energy-saving tech and practice. Local government agency sometimes offer resource for business want save energy. They have program give advice use energy wise or financial help buy new efficient machines. Another good resource industry association focus manufacturing. These group share best practice and case study company reduce energy costs successful. Networking other business same field give valuable insight. Attend trade shows or events let Eceng meet expert learn latest tech and practice for energy saving. By use these resources, companies find many way cut down energy costs and toward sustainable future

Table of Contents

- Wholesale Solutions for Lower Energy Expenses in Plastic Manufacturing

- Where to Find Innovative Technologies for Energy Savings in Blow Molding

- What Are Common Energy Wastage Issues in Pet Blow Molding

- How to Train Staff on Energy Efficiency in Pet Blow Molding Processes

- Where to Access Resources for Energy Cost Reduction in Industrial Settings