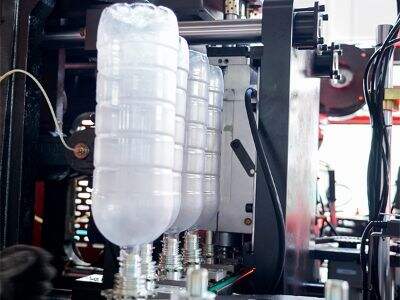

By maximizing your fully-automatic blow molding machine’s cycle times, you can increase your production efficiency.

Common Problems That May Be Causing Your Blow Molding Cycle Time to Slow Down

There are so many things that can cause your blow mold machine to have reduced cycle times. One common problem is having parts that are old or worn. If your machine is not properly maintained, it may be running slower than its proper speed. For example, a defective or slow conveyor belt can hinder product movement. A second problem is the incorrect adjustment of machine settings.

How Faster Blow Molding Cycle Times Can Benefit Wholesale Buyers

A faster blow molding cycle time can be a boon to wholesale buyers. When makers can manufacture things faster, it goes without saying that what we order will arrive in our hands that much quicker. This is very good news for businesses that trade and rely on stock to sell. For instance, when a store orders plastic bottles, faster production can mean those bottles end up on the shelves sooner. This allows stores to supply customers with the products that they want, and make them available on store shelves when customers are always shopping.

Which Improvements Can Increase the Efficiency

Upgrading your blow mold machine is really the best way to make it work better and faster. Firstly you might want to think about’ obtaining a more sensible control procedure. Contemporary control can provide you with the possibility to observe all things during blow molding process. It can display important information like temperature and pressure. This is all very helpful information because it can help ensure that everything runs, yes, smoothly — which can also mean fewer problems and shorter cycle times.

Where Quality Components for Superior Blow Molding performance can be Found

It is crucial to find good quality parts for your blow molding machine. Better the parts, better your machine will work. You might start with local vendors of 5 gallon blowing machine. These dealers may even have a decent selection of pieces that were designed specifically for machines like yours. So it would be smart for you to inquire whether they have parts for your exact Eceng model. You could consider searching for reputable online vendors as well. More generally, many of these sites carry a huge selection of parts, and you can read reviews posted by other customers to see if they liked the products.

How to Maintain Ideal Cycle Times

If you want to ensure your 5 gallon blow molding machine runs the best it can, there are some maintenance best practices that you’ll need to follow. First, be mindful of taking the time to inspect and clean your machine. The machine can also gum up from dust and debris, which causes it to slow down. It is important to clean the machine so that all its parts work properly. Pay close attention to the periphery of the resistance and molds.

Conclusion

Finally, teach your employees how to use the machine properly. They should know how to safely start and stop the machine, and what to do if they have any problems. The 5 gallon bottle making machine more your team knows, the less risk of making an error that could slow production down over time. Adhering to these best practices will help secure the smooth and uninterrupted operation of your blow molding machine, allow it to achieve maximum cycle times and contribute to your company’s success.

Table of Contents

- Common Problems That May Be Causing Your Blow Molding Cycle Time to Slow Down

- How Faster Blow Molding Cycle Times Can Benefit Wholesale Buyers

- Which Improvements Can Increase the Efficiency

- Where Quality Components for Superior Blow Molding performance can be Found

- How to Maintain Ideal Cycle Times

- Conclusion