A Comprehensive Guide

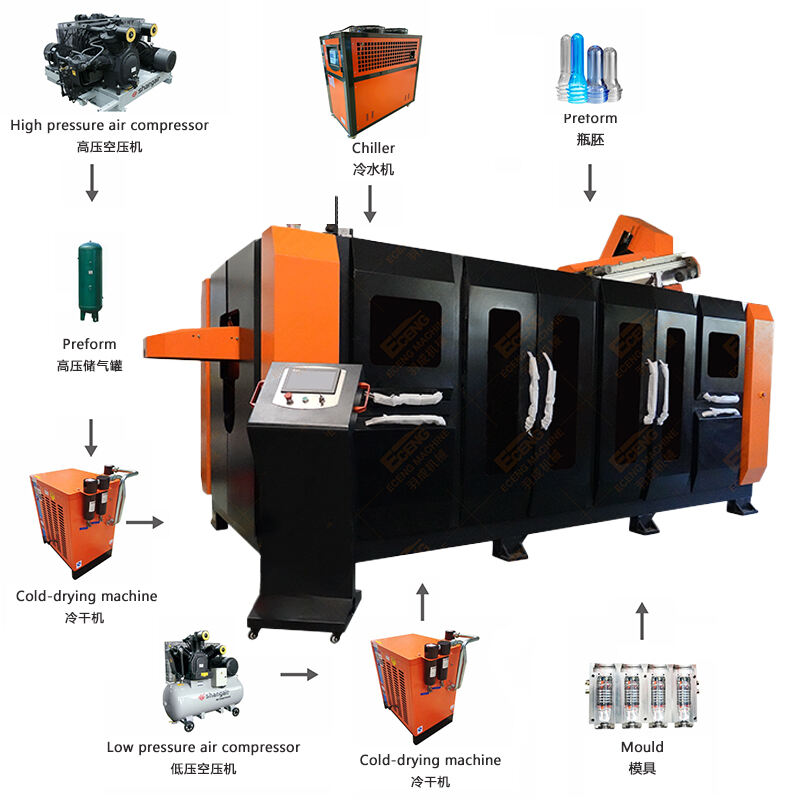

5-Gallon PET Blow Molding Machine needs to be maintained properly for its best performance and longer life. At ECE, we know that maintenance is critical to ensure maximum production. From the daily check-up to infrequent deep cleaning, it matters that you take proper care of your blow molding machine! Our in-depth guide includes the best ways to maintain your equipment, what you should check for when it comes to common problems, as well as top tips and expert advice so that you can keep your tools working for as long as possible

Critical 5-Gallon PET Blow Molding Machine Maintenance Tips

Keep Your 5-Gallon PET Blow Molding Machine Running Smoothly Here’s a few great pieces of advice to maintain your machine394448229.930244 Keep Your 5-Gallon PET Blow Molding Machine In Top Shape

Every day whilst using: You should be mindful of any wear & tear, for loose parts or strange noises. Take care of little problems before they turn into big headaches

Lubricate: Lubricate the moving parts to minimize friction and for proper working

Cleaning: Keep your machine clean often, this means inside and out to get rid off dust, debris and build up. You can use this machine without fear of problems and contamination

Calibration: In order to ensure production processes are precise, the machine must be calibrated frequently. Correct calibration allows for consistent quality output

Training: Be sure operators are trained in how to operate the machine and maintenance requirements. Well-trained workers may even be able to catch problems early enough so that the equipment can work more smoothly when it does run

Common Problems and Solutions of 5-Gallon PET Blow Molding Machine Maintenance

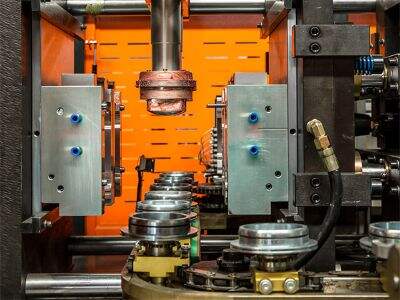

Even with good maintenance, problems can occur with your blow moulding machine. Issues such as inconsistent wall thickness, flashing and misalignment of the mold are common. It is of great importance to deal with them in time so as not to cause stoppages. By approaching the problem proactively, you can discover what caused the issue and start working towards a solution that doesn’t repeat itself

Make sure you consult the maintenance manual or get in touch with our Technical Department for any possible issue on the final product or failure of the machine. A timely intervention could also save time and money eventually

Tips for running 5-Gal PET Blow Molding Machines

Besides the regular maintaining matters, we should develop some good habits which will help improve 5-Gallon PET Blow Molding Machine performance and efficiency. Some best practices include

Schedule a Check-Up: Make up a routine check-up schedule for tasks on daily, weekly, monthly and yearly basis to avoid something left out for maintenance

Spare parts stock You need to keep up some key spare parts that would go a long way in providing quick fix for any sudden brake down. A parts inventory can reduce downtime and smooth production

Operator Training Programs: Commit to continuous training programs for operators that further their ability toward running and caring for the machines

Documentation: Maintain detailed logs of service, repair and operator comments to monitor how the machine is running over time. Documentation is the key to the discovery of patterns and improvements

Expert opinions How to keep 5-Gallon PET Stretch Blow Molding Machine in top notch

Recommended by our team of professionals at Eceng Machinery Co., Ltd., they suggest getting ahead on machine maintenance for peak performance and longevity. If you want to extend the service life of your 5-Gallon PET Blow Molding Machine, follow a detailed maintenance plan and troubleshoot common problems early, while adopting best practices and training operators. Our friendly expert team is ready to assist you with any enquiries so that your equipment will always serve you well. You can trust Eceng with turnkey blow molding systems that have been proven again and again to be efficient, as well as highly productive