16 Cavities Water Bottle Cap Making Machine Compression Molding Cap Machine Plastic Bottle Press Molding for Mass Production

Spu:

1601676869441

- Technical Parameter

- Recommended Products

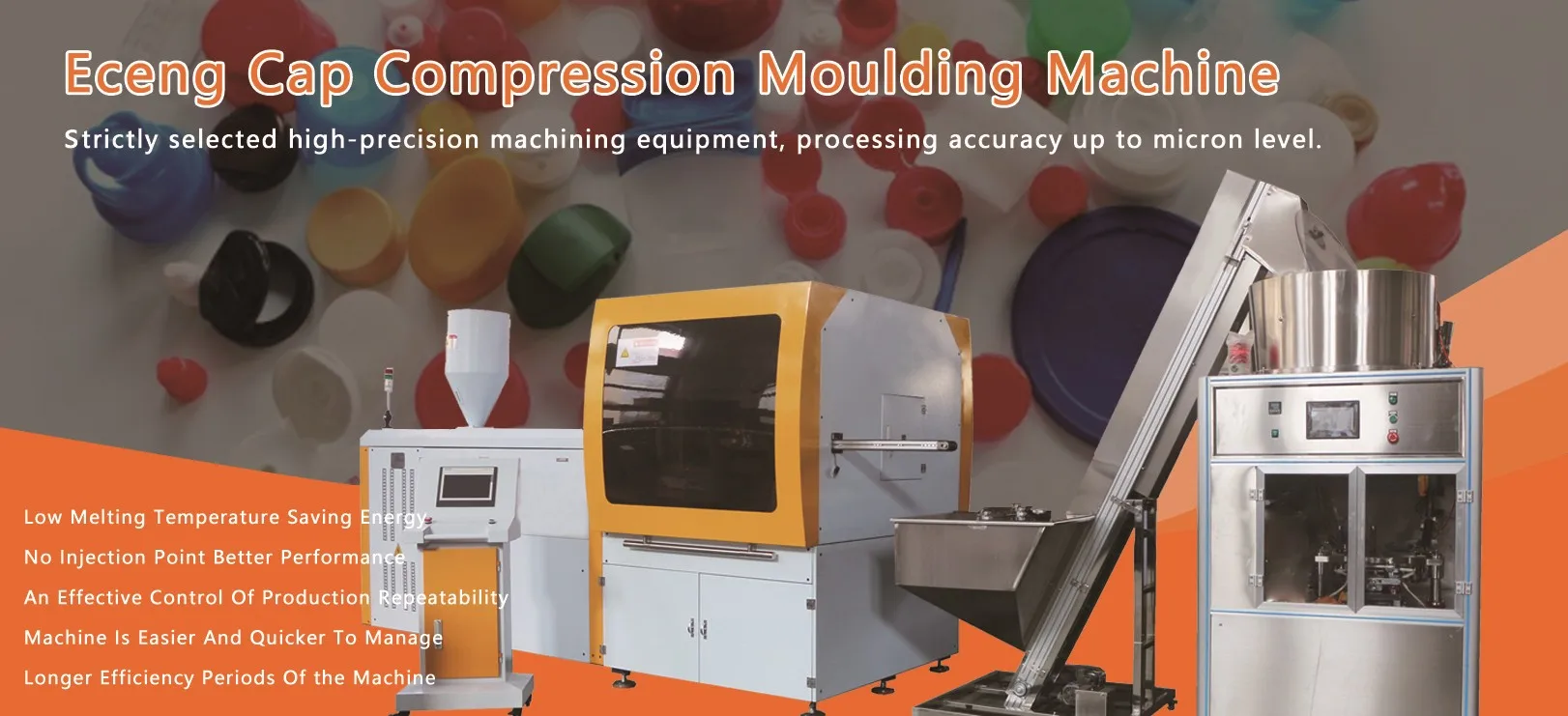

Eceng cap compression moulding machine

Eceng full automatic high speed cap compression moulding machine adopts hydraulic clamping principle, technic of rapid prototyping and mould release of low pressure, etc.to manufacture with continuous totation, widely used in the manufacture of bottle caps of carbonated beverage, mineral spring water, cosmetic products.The maximum productivity can reach 45000pcs one hour.

Model |

18T |

|||||

1 |

Output Capacity |

16000-21000 |

||||

2 |

Cap Diameter |

20-60mm |

||||

3 |

Cap Height |

10-30mm |

||||

4 |

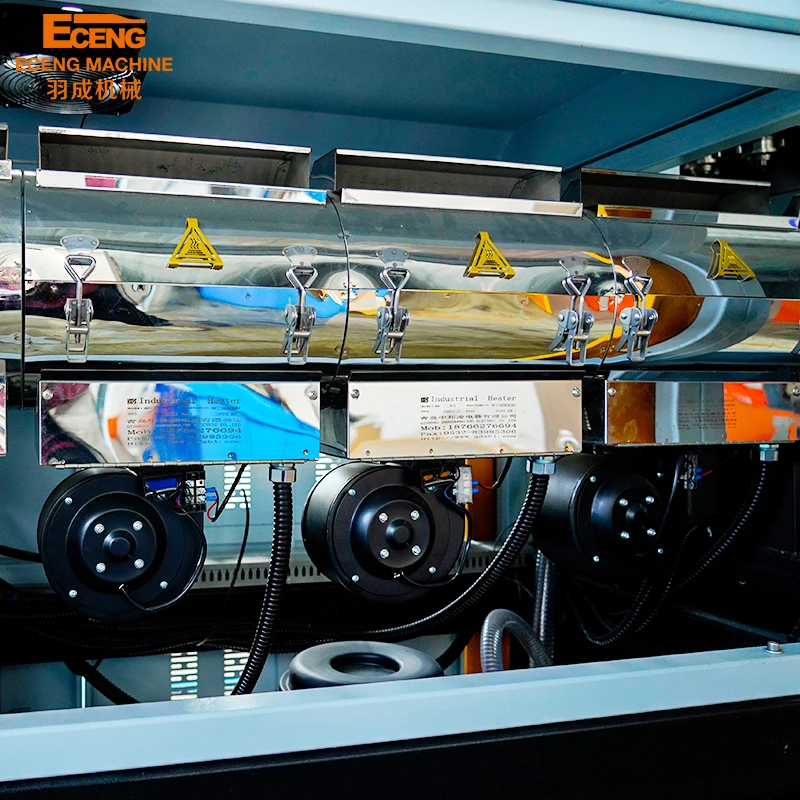

Extrusion Heating Power |

11KW |

||||

5 |

Extruder Motor Power |

7.5KW |

||||

6 |

Cap Material |

PE/PP |

||||

7 |

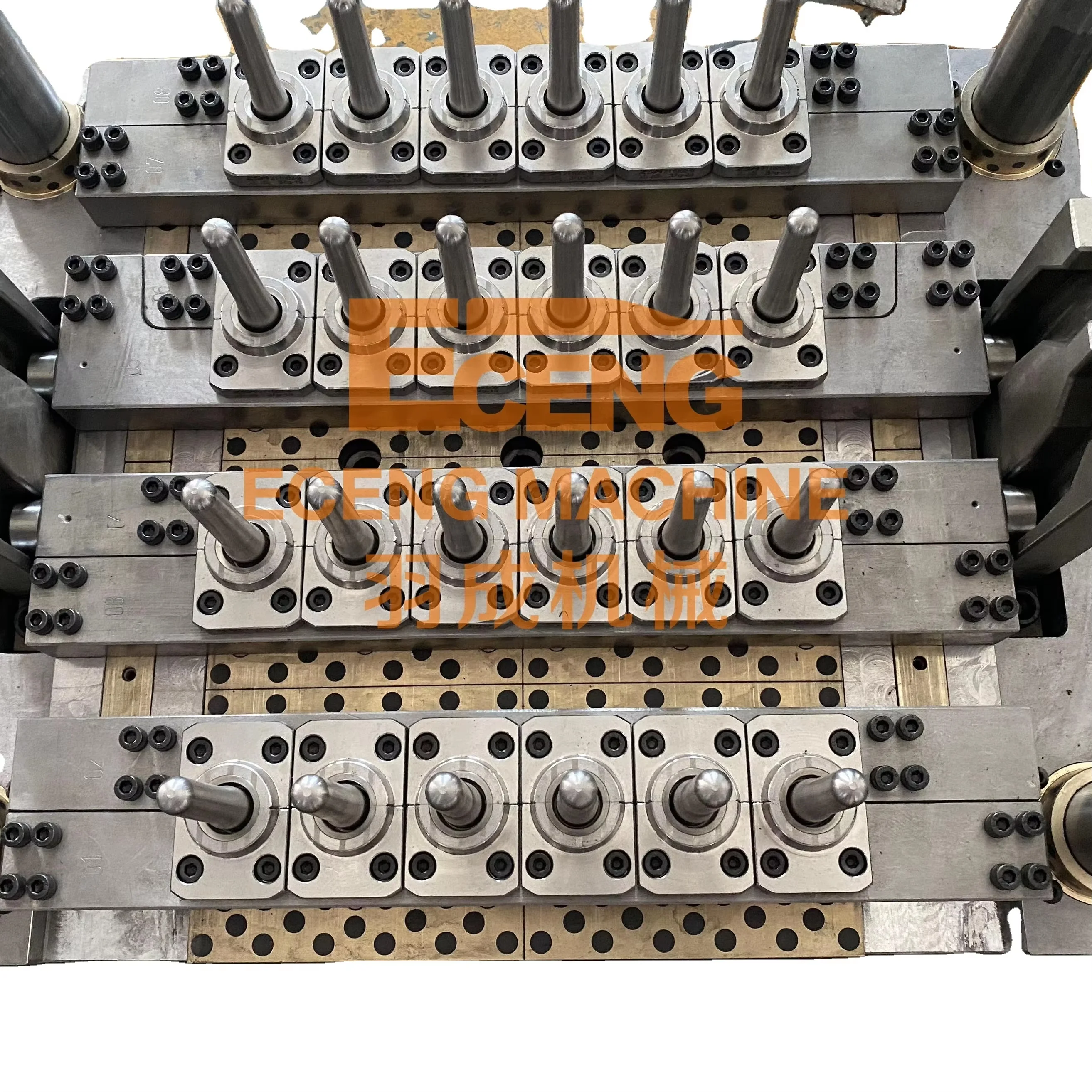

Cavity No. |

18 |

||||

8 |

Mold Compression Motor |

2.2KW |

||||

9 |

Hydraulic System Power |

11KW |

||||

10 |

Power Supply |

380V/50HZ |

||||

11 |

Air Consumption |

0.3m³/hr,0.8Mpa |

||||

12 |

Machine Dimension |

3.3*1.4*2.1m |

||||

13 |

Machine Weight |

3500KG |

||||

Lower cost, higher productivity

Output threefold vs. plastic injection

Easy to assemble and disassemble

Great cap quality, stable grammage

Quick mold change, less downtime

Optimized design, user-friendly touch control

Compact size, easy to handle

water plastic closure

Cold Fill plastic closure

CSD BCPL plastic closure

1, The machine bottle production process without the injection point, good bottle products, beautiful appearance.

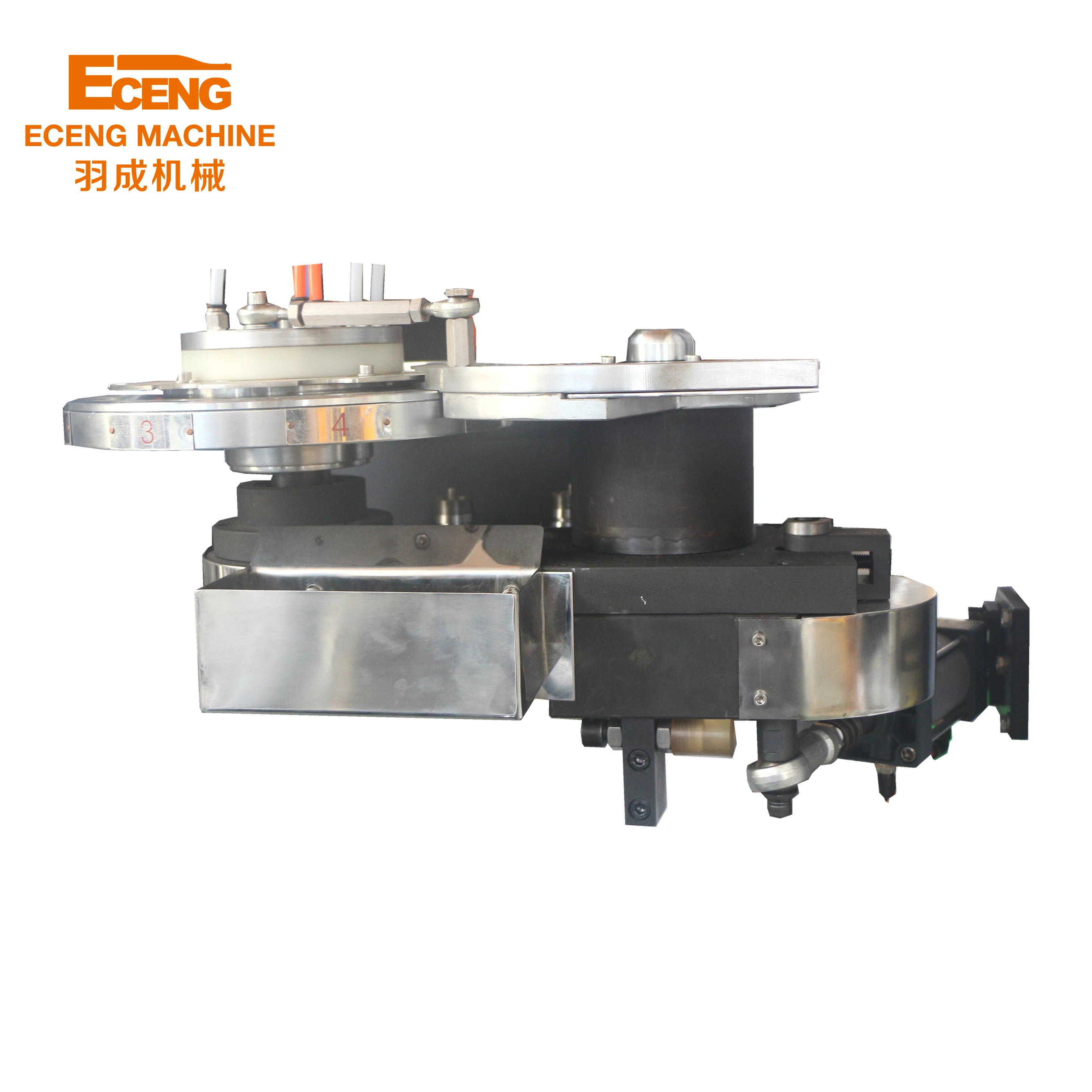

2, The machine adopts multi-speed rotating grinding repression approach to production, to ensure high productivity.

3, The machine rotary manner aeroassisted quit threaded mode, to avoid stripping the thread damage caused strong.

4, The machine is compact, fully automated operation.

5, The machine replacement material molds convenient and easier maintenance festival time.

We Have The Right Products to Fit Your Needs Purchase

Zhangjiagang Eceng Machinery Co., Ltd., established in 2007,Our factory spans over 10,000 square meters, and we hold independent research and development patents. We offer a comprehensive production system for PET liquid packaging.

Our main products include fully automatic and semi auto bottle blowing machines, self-adhesive labeling machines, OPP labeling machines, sleeve labeling machines,baler,Film shrink wrapping machine, carton packing machines,palletizing machines, blow moulds, injection pet preform mold, bottle cap molds, Bottle cap compression molding machines, air compressors, cold dryer, and chiller.

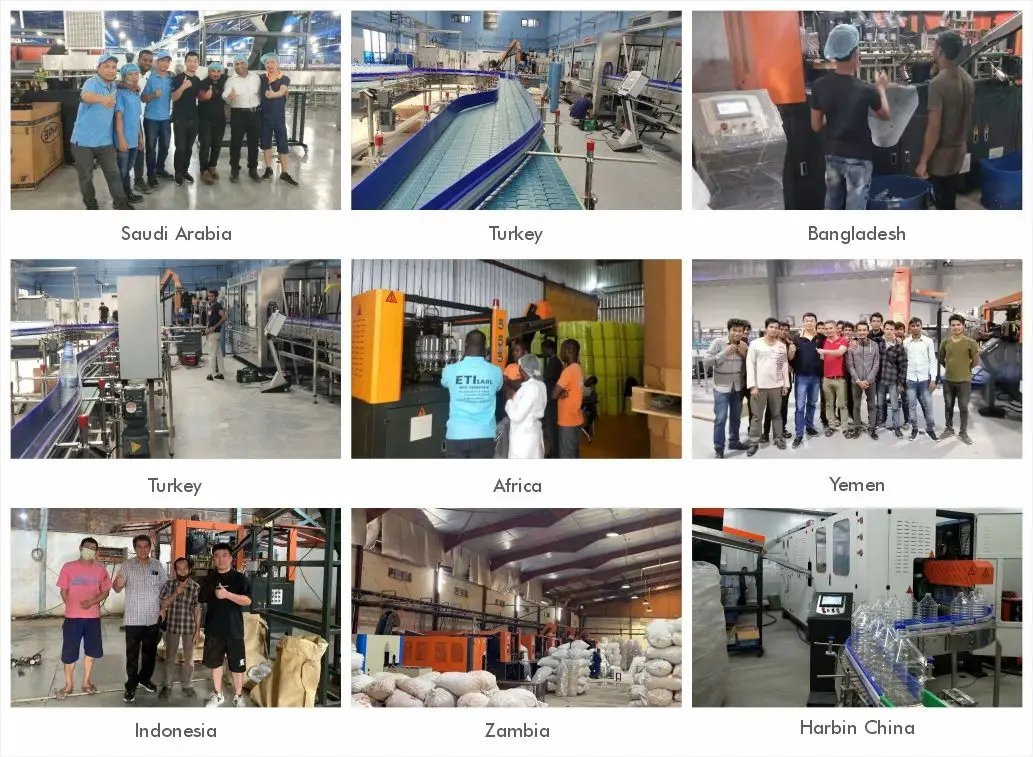

As a leading one-stop service provider in PET liquid packaging, we supply factory direct products to over 170 countries and look forward to building long-term partnerships worldwide!

Exhibition and Customer Visit

Packaging & Shipping

FAQ

Q:Your company is a trading company or a direct factory?

A:We are a direct factory which locates in Zhangjiagang city. in close proximity to Shanghai and Wuxi. If you arrive at either Shanghai or Wuxi, we can arrange transportation to pick you up and accompany you for a visit to our factory.

Q: How can I know your machine works well?

A: Before delivery, we will debug the production line, take photos, videos and send them to you via mail or instant tools.And you are welcome to come to visit our factory,and see the machine running.

Q:All of your products are made by yourself or compacted via purchasing the others?

A:We have independent technical team who focus on making machines,all the products are made by our technical team.