Eceng Pet Preform Maker Car Glass Water Bottle Mold for Injection Molding Machine Good Price

- Technical Parameter

- Recommended Products

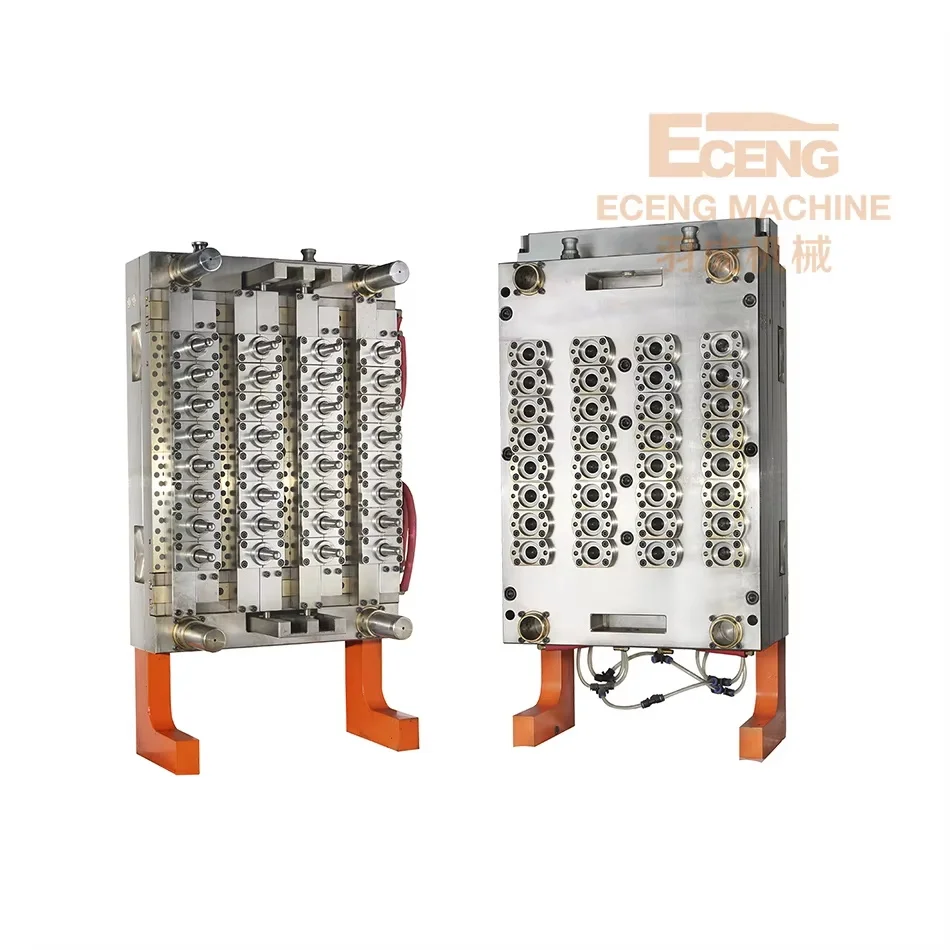

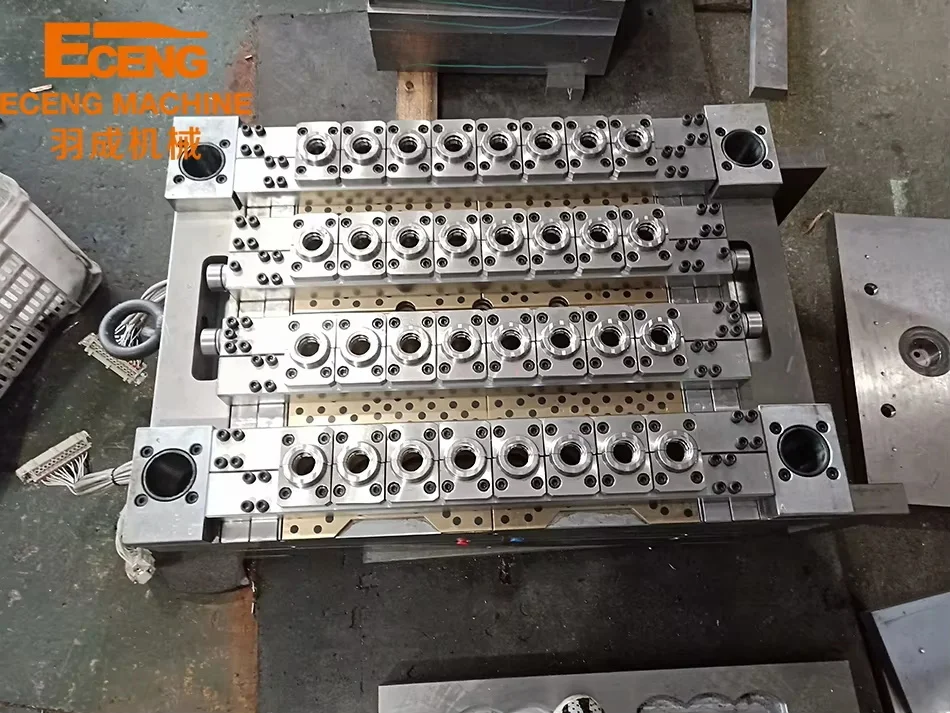

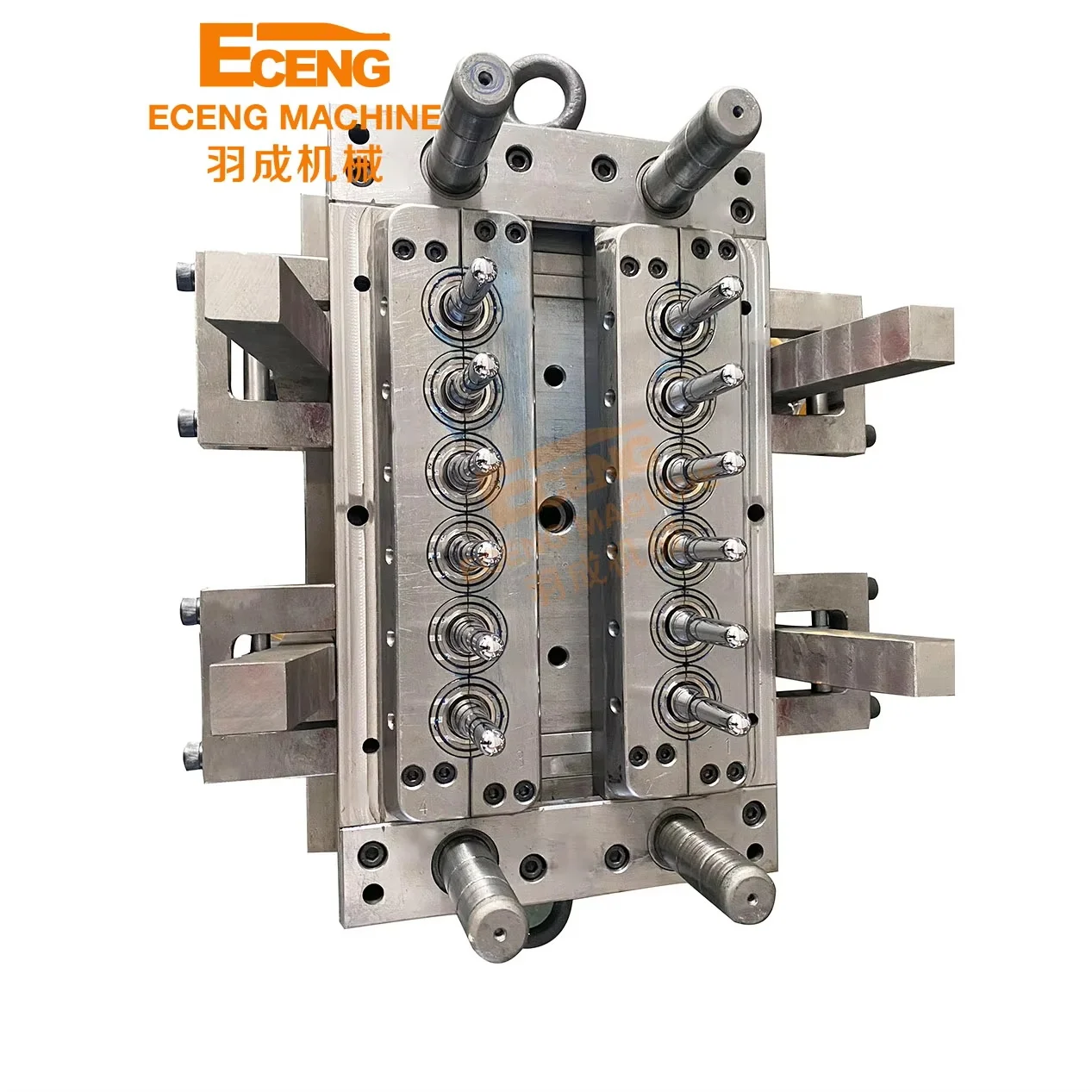

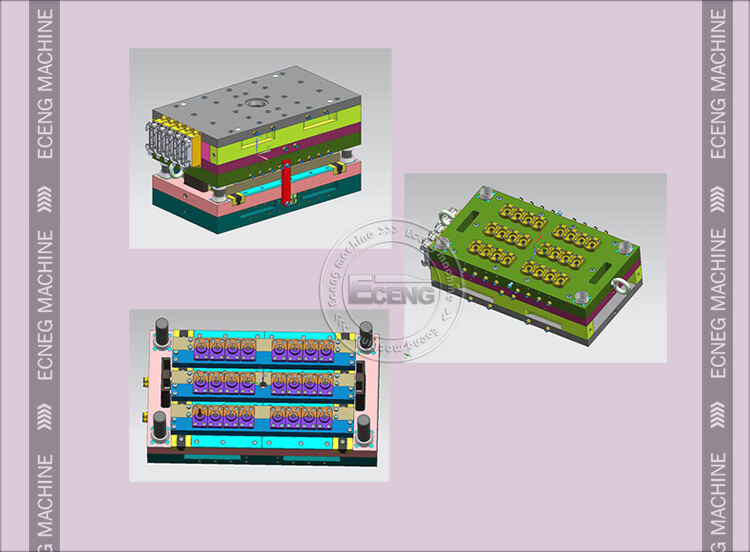

Introducing, the Eceng Pet Preform Maker Car Glass Water Bottle Mold for Injection Molding Machine! This top-of-the-line mold is the perfect solution for creating high-quality car glass water bottles with ease and efficiency.

The Eceng brand is synonymous with durability and reliability, and this mold is no exception. Crafted from premium materials, this mold is built to last and withstand the rigors of frequent use. Whether you are a professional manufacturer or a hobbyist, this mold is sure to impress with its superior craftsmanship and attention to detail.

With its user-friendly design, this mold is incredibly easy to use. Simply attach it to your injection molding machine and watch as it effortlessly shapes molten plastic into a perfect car glass water bottle preform. The precise dimensions and smooth finish of the preform ensure a flawless final product every time.

One of the key features of this mold is its versatility. It can be used with a wide range of materials, making it suitable for a variety of applications. Whether you prefer PET, HDPE, or any other plastic resin, this mold can handle it with ease. This flexibility allows you to create custom car glass water bottles that meet your exact specifications.

In addition to its exceptional performance, this mold is also incredibly affordable. At a competitive price point, it offers great value for money and is a cost-effective solution for any business or individual looking to produce car glass water bottles. Plus, with its durable construction, you can count on this mold to provide reliable results for years to come.

The Eceng Pet Preform Maker Car Glass Water Bottle Mold for Injection Molding Machine is a must-have tool for anyone in the plastic manufacturing industry. With its superior quality, user-friendly design, and affordable price, it is sure to exceed your expectations. Upgrade your injection molding process with this outstanding mold from Eceng and experience the difference for yourself

The Specification Of Hot Runner Preform Mould |

||

Cavities |

32-cavities |

|

Mould frame material |

4Cr13 Stainless steel |

|

Core material |

S136 |

|

Cavity material |

S136 |

|

Valve Pin Brand |

SKD61 - Japan |

|

Heat insulation tip Brand |

DuPont - America |

|

Heater ring brand |

Hotest - Germany |

|

Runner structure |

||

Enter runner |

One gate |

|

Base runner |

4 points |

|

Sub channel |

32 points |

|

Mould information |

||

Mold outline size |

780x560x590mm |

|

Mould weight |

1300KGS |

|

The mould features |

Self-lock, air seal, valve gate |

|

Cycle times |

20 seconds |

|

Mould power |

9 kw |

|

After-sales Service |

||

Mould life |

More than 3 million shot injection times |

|

Guarantee period |

One Year |

|

Payment terms

|

30% deposit in advance |

|

70% balance before shipping |

||

Packaging requirement |

Standard export packaging |

|

Product information

|

Neck size:28mm |

|

Weight:20grams |

||

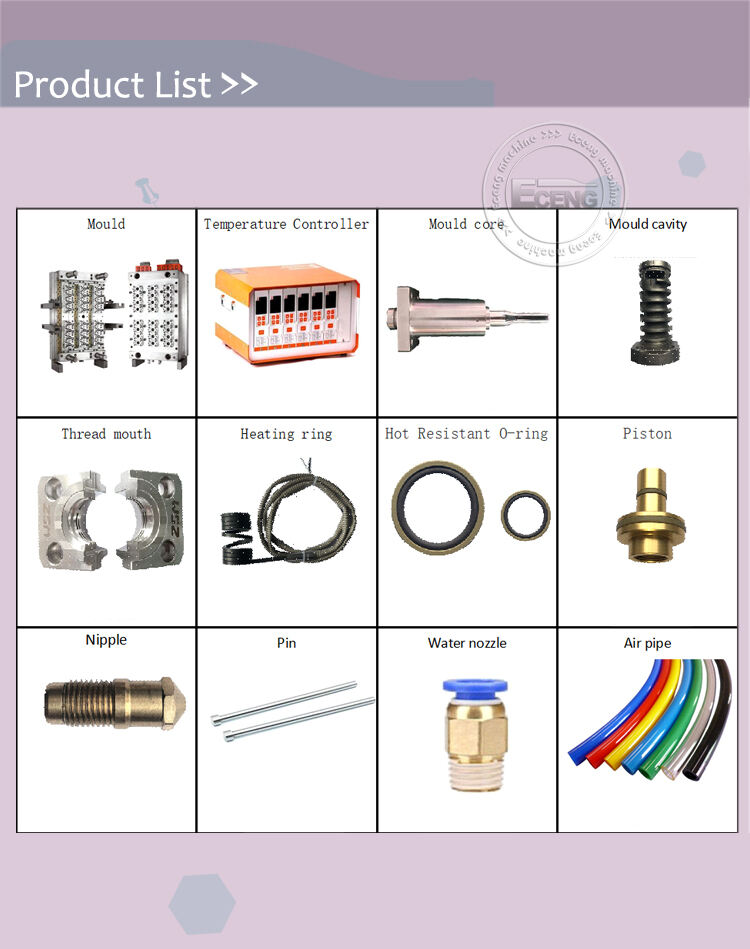

Zhangjiagang Eceng Machinery Co., Ltd. is a professional provider of comprehensive blow-molding packaging solutions in China, integrating three specialized factories (mold factory, blow-molding machine factory, and packaging machine factory). We deliver fully automated solutions—from molds to blow molding, packaging, Palletizing, and conveying—significantly reducing production costs. Our main products include: various molds, blow-molding machines, integrated filling and capping machines, oil/water filling production lines, labeling/sleeving equipment, and case-packing machinery, widely applied in beverages, food, daily chemicals, and other industries. All products are CE-certified and comply with international quality standards

We are based in Jiangsu, China, start from 2010, sell to Southeast Asia(30.00%), Africa(20.00%), Domestic Market(20.00%), Mid East(15.00%), South America(10.00%), North America(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us

Fully Auto Bottle Blowing Machine

4. why should you buy from us not from other suppliers

We have been committed to the design of plastic bottle making machine, especially the fully-automatic PET blow mould machine, from 300ml- 20L. Our machine complying with CE certification has good quality with praise by our customers.

5. what services can we provide

Accepted Delivery Terms: FOB, CIF, EXW;

Accepted Payment Currency:USD, EUR, CNY;

Accepted Payment Type: T/T, L/C, Western Union;

Language Spoken:English, Chinese