Plastic Processed:

PET

Max.Bottle Height(mm):

330 Mm

Neck Diameter(mm):

38 Mm

Max.Bottle Diameter(mm):

100 Mm

Bottle Volume(ml):

2000 Ml

Condition:

New

Application:

Bottle

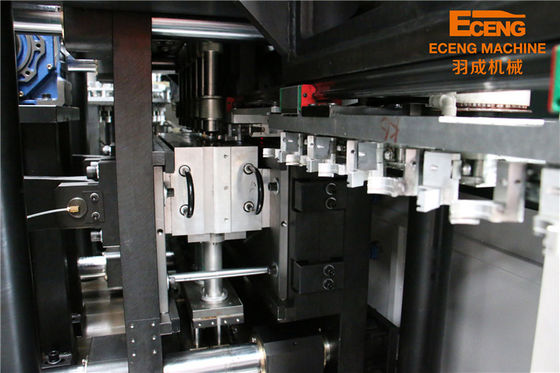

Blow Moulding Type:

Stretch Blow Moulding

Year:

2019

Voltage:

380V,50HZ

Dimension(L*W*H):

5.5*1.8*1.9m

Hollow Part Volume:

2L

High Pressure Valve Brand:

SMC

Rotary Cylinder Brand:

SMC

PLC Brand:

DELTA

Power (kW):

49

Weight (KG):

6100 KG

Automation:

Automatic

Warranty:

1 Year, One Year For Free

Key Selling Points:

Automatic

Showroom Location:

Pakistan, Viet Nam, Canada, Brazil, United Kingdom, Indonesia, Germany, Egypt, Philippines, South Korea, Algeria, Chile, UAE, Uzbekistan, Nigeria, Argentina, Romania, Australia, Ukraine, Kyrgyzstan, Malaysia, Kazakhstan, Tajikistan, Bangladesh, Kenya, Sout

Applicable Industries:

Food & Beverage Factory

Automatic:

Yes

After-sales Service Provided:

Engineers Available To Service Machinery Overseas, Field Maintenance And Repair Service, Video Technical Support, Free Spare Parts, Online Support, Field Installation, Commissioning And Training

Color:

Black And White

Warranty:

1 Year

Output:

10000

Size Of The Machine:

5.5*1.8*1.9

Weight:

6.1tons

Power(W):

50KW

Local Service Location:

Viet Nam, Pakistan, Saudi Arabia, Germany, Egypt, Mexico, Indonesia, Canada, Brazil, South Africa, Chile, Malaysia, Kyrgyzstan, Argentina, South Korea, Kenya, Bangladesh, Algeria, Colombia, Sri Lanka, Ukraine, Nigeria, Tajikistan, Australia, Romani

After Warranty Service:

Spare Parts, Field Maintenance And Repair Service, Video Technical Support, Online Support

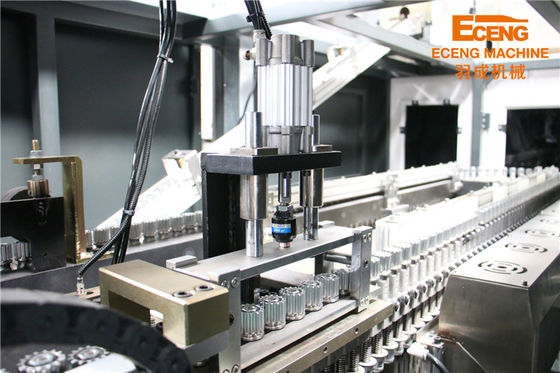

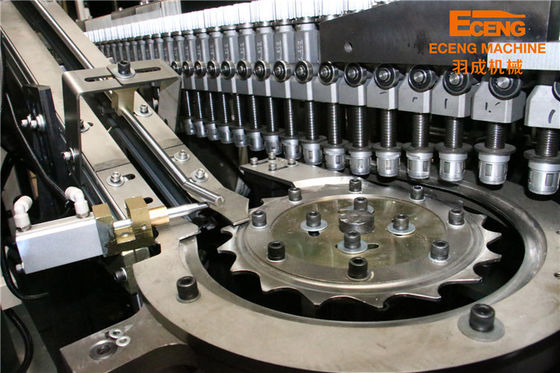

Production Capacity (BPH):

10000 BPH

Port:

Shanghai

Highlight:

6 cavity PET bottle blowing machine

, 6 cavity pet blowing machine 49kw

, 6 cavity pet blowing machine 6kg/cm2

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!