What Makes Pet Stretch Blow Forming Machines Incredible Pet Stretch Blow Forming Machines are fabulous machines that help with the production of bottles and containers from a specific type of plastic known as PET. They are used in numerous industries to produce all sorts of bottles that we see every day, whether for water, soda or even shampoo. Today, let’s delve a little further into these awesome machines and how they work.

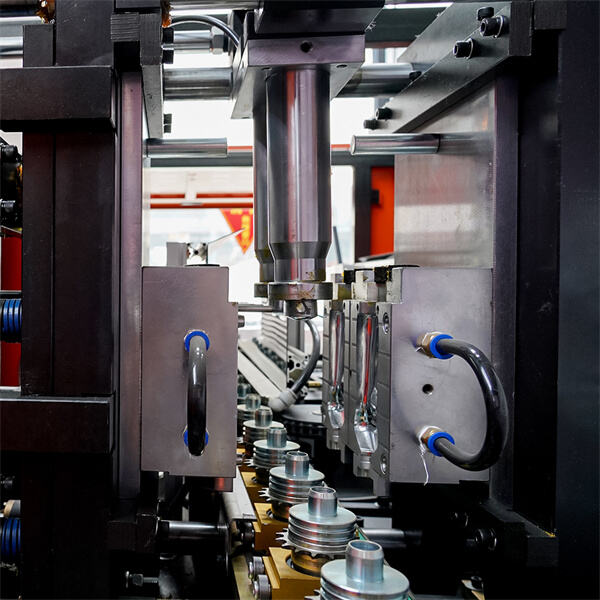

The Pet Stretch Blow Forming Machine is equipment that creates bottles and containers out of plastic by using heat and air. It does so by heating a tube of plastic, or preform, until it is soft and malleable. Air is then blown into the preform, stretching it to the shape of the mold in the machine. This method tends to make sturdy reusable bottles that can take a beating and carry all sorts of liquids.

There are advantages of using a Pet Stretch Blow Forming Machine. Among the major benefits is the ability for businesses to make their own bottles and containers in-house, saving time and money. These machines are also highly productive and can make a lot of bottles in very less time. Furthermore, bottles made with a Pet Stretch Blow Forming Machine are light in weight but still strong allowing them to be moved around and stored without worry of damaging them.

The Pet Stretch Blow Forming Machine looks complex but it is very easy to use. 1) PRE-FORMS are loaded to the HOPPER of machine, and being heated to the necessary time and temperature. The performs are then moved to the mold cavity where they are stretched and blown into the desired shape. After the bottles are molded, they are cooled and ejected from the machinery. It's crucial to follow the manufacturer’s instructions to the letter, or your H3 3 Cavity 2800BPH Hand Feeding Wash Bottles Blowing Machine may not work well and the bottles may not be high quality.

All machines, including Pet Stretch Blow Moulding Machines are not perfect and are not meant to be perfect for ages. Some problems are due to non-uniform heating of preforms, insufficient stretching of the plastic and air leaks in the system. For such problems, operators must go through the machine settings, mold cavity inspection, and perform tightening of loose connection. You can also avoid problems from ever happening by keeping everything cleaned and well-maintained.

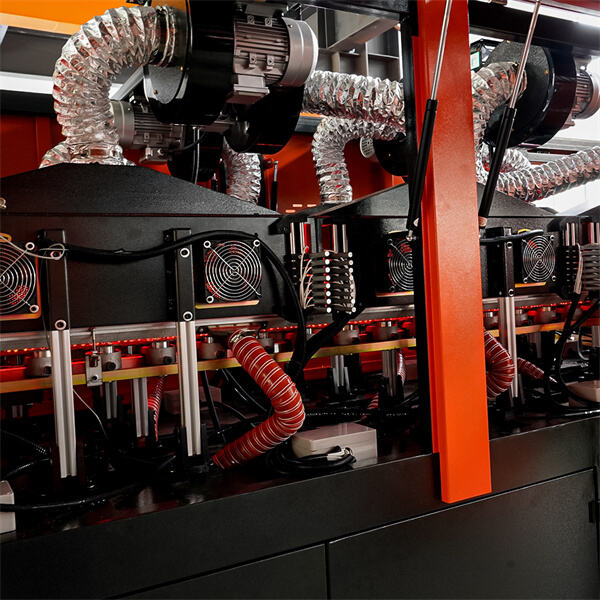

With the advancement of technology, Pet Stretch Blow Moulding Machines too are changing. Latest machine design and material technology now ensure even more productivity and reliability from these machines. Machines with sensors are already introduced, that are capable to identify issues in real time and help to fix problems quickly and avoid downtime while increasing productivity. 3) Advancements in Mould Technology With the use of state of the art mold technology ‘complex’ and ‘creatively design bottle shapes’ can now come to life.