Bottle making is a crucial job in lots of factories, and the right way to make them is even more important. When it comes to accuracy with bottle forming, stretch rods are significant. A stretch rod forms the bottle as it is made. Get the sheaves turning too slowly or too quickly and bottles may not turn out properly. At Eceng, we strive to achieve the best speed for our stretch rod. This means we can make higher quality bottles that fit our customers.

How to Increase Speed of Guides for Stretchg Rods in High Precision Bottle-Forming

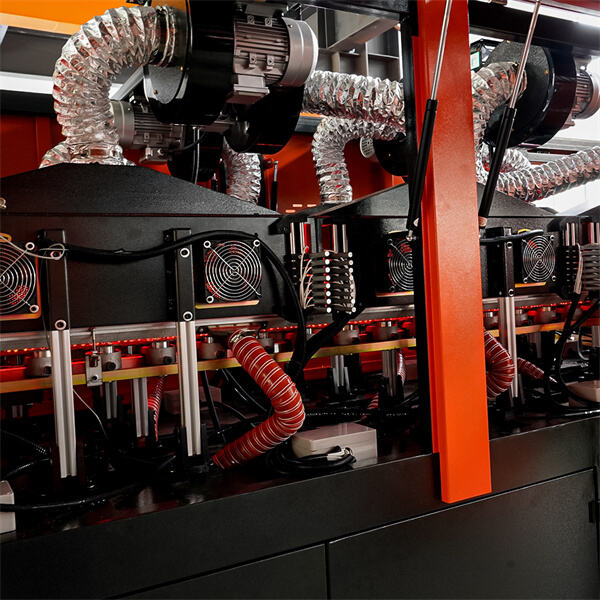

We can work on some key areas to make the stretch rod faster. First off, the machine settings need to be checked. Each machine is different, and little adjustments can make all the difference. For example, if the rod is too slow, the bottle might be misshapen. But if it’s too fast, the bottle can crack. And it’s critical to find that sweet spot. One other approach to increase the speed is to service your machinery. Stretch rods are tools that, like any other, need care. They work better, with regular cleaning and lubrication. Dirty or rusty rods can be a hindrance to that process.

It is also important to train the staff. The workers can adjust energies when they know how the machines are operated properly. For instance, if they notice that the bottles are not forming properly, they can adjust the speed immediately. The process is what you watch. Using technology can help too. In many appliances, sensors can now track the speed in real time. If something goes wrong, the machine can alert the workers. That way, if somebody has a problem, you can correct it.

Finally, regular testing is important. With small changes and a little bottle testing, we can determine what works best. Continuous improvement is something we believe in and it reflects our ethos at Eceng. That is to say, we are constantly seeking to improve our process. We can optimize stretch rod speed with these measures and prevent our bottle forming to be accurate.

What are the Advantages of Running Stretch Rod Speed on Optimum in Bottlers?

There are many advantages of the optimization speed of stretch rod in blow forming machine. First up, it results in a higher quality bottle. And when the speed is perfect, the bottles emerge smooth and sturdy. They have the ability to carry water without leaking, which is of great importance for customers. Customers love great bottles and happy customers come back. It’s a huge victory for companies like Eceng.

Another benefit is efficiency. The machines can work faster when the stretch rods are tuned out. This allows for making more bottles in less time. If a factory can produce 1,000 bottles of a thing in an hour rather than 800, that is a big difference. The more bottles they have, the more they are able to sell and that’s good for business.

Cost savings are also important. When machines work well, they use less energy. This means lower electricity bills. Plus, the fewer defects for bottles, the less waste. If a bottle is manufactured incorrectly, its body might have to be discarded. Reducing waste saves money.

And, in addition to that, speed as an optimization might also help safety. So the stretch rods, if they are moving at the correct speed, have less of a potential for accident. Fewer workers are hurt when machines operate as intended. A safe place to work is best for all.

Although it may not appear to be the case, stretching rod speed is just another ingredient of bottle making success - and focusing on this will help you produce higher quality, work more efficiently, save money and reduce injuries. That is why we, at Eceng, are able to provide better quality drinking water bottle making plant. We want to ensure that our bottles remain at the highest quality level, yet still keep our business operations running.

How Do I Solve Stretch Rod Speed Issues and Boost Bottle Quality?

When shaping bottles, getting the stretch rod speed right is a key thing. If too fast or too slow, it can result in challenging issues with the bottles. For instance, if the stretch rod is traveling too fast, the bottles may not properly take shape. They may contain bubbles or weak points. Alternatively, if the stretch rod is moving too slow, the bottle may become overly thick and heavy. To solve these speed issues but not the dancing gnomes you may want to start with machine settings. Make certain that the stretch rod speed is adjusted to the type of bottle you are producing. Different bottles need different speeds. Then watch them being made. Inspect for any warning signs, such as lumps and asymmetry or cracked skin. If you spot any problems, experiment with the speed a touch. Sometimes all you need is a tiny tweak. It is probably worth paying attention to the materials you’re using, too. If the plastic is not the right type for the bottle, it may cause issues with forming. Run it with good quality materials that are compatible with your machine. You might also think about the temperature of things. If the plastic is too cold, you’ll have a harder time stretching it. It can be even too soft if it’s that hot. Dialing in that temperature control can help the stretch rod work more effectively. Finally, be sure keep the machine clean and adequately serviced. Dust and dirt it attracts will interfere with how the stretch rod maneuvers. Regular upkeep will keep your ship sailing. If you check these things, you may be able to solve speed issues and bottle better.

By Brian Hughs Buy Stretch Rods for Bottle Forming – Where Do You Find The Best Quality?

It is very important to find the suitable stretch rods for good quality bottles. Eceng only supplies customers with the very best of Plastic rods because at Eceng, we think that using poor quality rod will produce low quality end product. To collectively source these rods, one must first turn to proven distributors. You can look online or check with other bottle makers for suggestions. Look for a supplier that is reputable when picking one out. They should be able to offer specific details of their products and have great reviews online from other customers. Also useful is a question about whether they have any samples. By testing a sample you will be able to determine if the stretch rod works well for your machine and materials. Also, you should think about the material of your piercing stretch rods. They should be strong, and resistant against stretches. Common materials are stainless steel or high strength plastic. Ensure that the rods are purpose made for bottle blowing machine. This will take the guesswork out of whether they will fit your gear or if you can count on them to produce decent results. And you may want to see if the supplier can provide customizing services. Occasionally, you may require a particular size or shape for the stretch rods. You need a company that can produce custom rods to fulfil your specific requirements. Lastly, consider the price. It’s just as crucial that you search for quality rods, making sure they are comprised of high-quality materials, without breaking the bank. Shop around to get the best possible deal. Just remember, spending a few extra bucks on good stretch rods will be worth it in the long run when you have perfect bottles.

What Are The Wholesale Solutions to Improve the Performance of Stretch Rod?

The wholesale strategy can be a brilliant idea so that stretch rods can perform better. At Eceng, buying in bulk becomes profitable to you and, at all times, you get sufficient supply of quality bottles. A good alternative will be to find wholesale suppliers that focus on stretch rods. The deals that these suppliers tend to offer are typically discounts on buying a large number of rods and, thus, a good stock of the high-quality rods become accessible. During the communication with wholesale suppliers, ask them about their product line. There are a limited number of companies which present various forms of stretch rod sets. You can find rods that have special coating which makes them reduce friction or made of space-age materials which wear better. This could improve work and reduce fatigue. You may also consider buying several products on top. As an example, you might need other articles or accessories that can be fitted to the stretch rods. Being able to have one supplier of it all would save time and money. Some wholesalers as well offer technical support and resources. This can come in handy should you have any questions of how to utilize the rods or on how to improve the abilities of your machine. Do call up the suppliers and ask them to help, or give tips; some are more than glad to help. Finally, remember to check on promotions or specials. The wholesalers often offer sales or discount options which can enable you to save even more. These bulk options are in mind when you can even make your stretching rods do better in order to make better the quality of the bottles you produce.

Table of Contents

- How to Increase Speed of Guides for Stretchg Rods in High Precision Bottle-Forming

- What are the Advantages of Running Stretch Rod Speed on Optimum in Bottlers?

- How Do I Solve Stretch Rod Speed Issues and Boost Bottle Quality?

- By Brian Hughs Buy Stretch Rods for Bottle Forming – Where Do You Find The Best Quality?

- What Are The Wholesale Solutions to Improve the Performance of Stretch Rod?