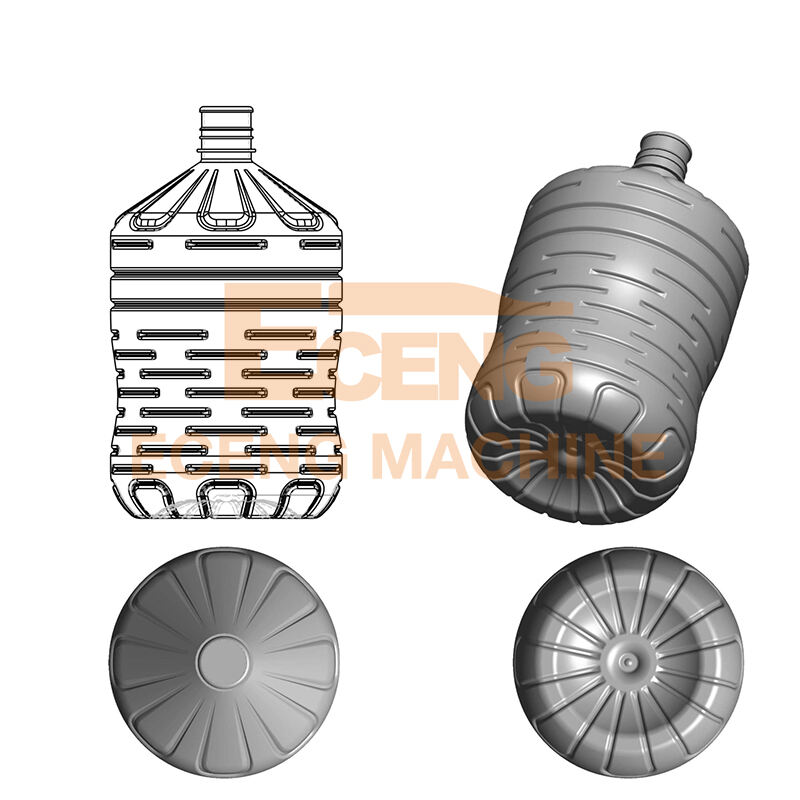

It’s really important that we use less, a lot less material when we do start of the PET blow molding process. I think that when we start really making, there’s a fair amount of waste. This is how robots get assembled or new designs tested. At Eceng, we know that Saving the material, not only to save the cost for packaging. By learning how to waste properly during startup, we're doing two things: Not only are we improving our processes and making them more efficient. It’s a matter of utilizing the proper methods, and being intelligent in how we approach our work. Here we’re going to examine how can that be possible.

Effective Startup Practices to Minimize Waste in PET Blowing Production

A good startup should be realized in order to reduce waste material during PET blowing. Before you begin, check over all the machines and tools to ensure that everything is in working condition. If a machine isn’t working right, it can waste a lot of material. If the temperature settings are incorrect, for example, the PET may not melt correctly, resulting in defects and scrap. Additionally, very careful measurements when setting up will help a bunch. It might be the case that for things like materials, if we could pinpoint precisely what is the minimum amount of material necessary, we avoid generating too much. Also, staying mindful of the production runs is a useful tip. Should we catch any problems, such as a leak or a clog, fixing them immediately can save us plenty of material. An important part of the puzzle is training the workers to use the machines correctly. When they are given clear instructions they can follow, they prevent mistakes that result in waste. Don’t let recycling escape your mind, either. That’s an important move, as picking up scraps and reusing them adds up. Instead of wasting scraps, you can recycle them on subsequent runs thus reducing waste.

Collaborative Strategies for Reducing Waste in Blow Molding Operations

It can be somewhat challenging to come up with effective waste reduction solutions when it comes to blow molding machine, making it a sort of obscure technique in the world of manufacturing, but whether you think about it or not is entirely on you, because just like any other industry trick the methods of creating more profit by saving plastic don’t change! One great way to learn about new ideas is to talk with other professionals in the field. Networking with other companies or participating in industry groups can result in learning better ways to slash waste. There are also plenty of online resources that can be useful. Advice from professionals who have been there, on websites and forums. You can also learn how to do this by seeing the field experts in action. When we look to other companies that are effectively dealing with their waste, we can use some of those tactics for our own applications here at Eceng. It would also be good to set up technology that can track levels of material use. When we deploy software to monitor how much material is used and wasted, we can identify areas in need of clean energy intervention. Finally, stay in regular contact with your team. Bouncing ideas off one another and talking out challenges can generate new solutions. Through that collaboration and sense of shared responsibility, waste reduction becomes a common goal. There are small acts that we can partake in which will have a positive effect for our business and the world around us.

What Are the Common Causes of Waste in Blow Molding Production?

When producing plastic bottles or containers though blow moulding you will want to understand why you get waste and what causes it. At Eceng, there are some repeat problem areas which can result in start up waste. One potential disruption is to not have the machines set properly. Too high or too low a temperature and the plastic may not melt right. This could result in the material hardening in an incorrect form or not filling the mold entirely, resulting in waste/trimmed parts. Another problem is also getting the machines prepared. If a machine is not sufficiently warmed up, or the mold is not set correctly, that can result in defects. That’s more wasted plastic, because we have to discard the bad ones and start anew.

Besides the risk of other negative impacts, if they are not cautious in working with it, operators may inadvertently spill or drop the material. This also adds to the waste. Even poor quality control checks can be a problem. If the team doesn’t catch errors fast, they may end up with too much bad stuff before they realize they have a problem. These are all problems that can contribute to a lot of extra work and a lot of material waste. At Eceng, we think that by recognizing these issues together we can solve them and cut waste. Regularly inspecting machines, training operators and improving processes are critical to ensuring such common problems don’t happen.

Reducing Waste to Reduce Cost of Goods in PET Blow Molding

Not only is PET blow molding with reduced waste good for the environment, it can save companies like Eceng money. One approach to reaping bulk savings is keeping a tight rein on the machines. That means watching every step, from the installation of the machines to the final checks before a product is sent out. Doing that sort of thing, we can catch problems early and optimize before we waste too much stuff. For instance, if the operators see that the temperature is off, they can correct it on the spot before too much plastic is spoiled. We can rely on sensors, and technology generally, to monitor this stuff so that we can begin to pinpoint when something seems off.

Another money saver is recycling any of the scrap we do have. We can, instead of simply tossing it out, compile it and return it to the production process. This plastic that is recycled can then go to making new products, so that we do not have to buy new plastic. At Eceng, we have the opportunity to put in place a system where all excess plastic is salvaged and recycled. This not only saves waste, but also saves us from spending in the long run. And training our team to be better stewards of waste can amount to big savings. When leaders are unified around ‘why we do what we’re doing,’ which is reducing waste, everyone notices things more about their work that they didn’t notice before and becomes more efficient, he said.

How To Educate Your Team On Waste Reduction Practices In Blow Molding?

Training your staff is an essential piece of the puzzle when it comes to how to reduce waste in blow molding machine. In Eceng, we think that as long as everyone knows it is important to reduce waste, they will make some smart choices at the production end. First and foremost, you want to have training sessions that define what waste is and how it can come about. Use illustrations relating to the world your students know, and offer examples from work of how a small mistake can waste tremendous amounts of material. Be sure to specify all the kinds of waste, including in excess material from defective parts or wasted time when machines aren’t set up properly.

Now, practical or practicum training is quite effective. Team can try setting machines and molds up properly. Show them how to test the temperature and pressure settings, and when something seems off. When employees can see how what they are doing affects the end product, they will generally be more focused. You might also find it helpful to develop an operator checklist for the startup procedure. This list can serve as a cue to check settings, inspect the molds and scout for indications of waste.

And last but not least create an atmosphere for communicate! If someone sees an opportunity, they should be encouraged to speak up and offer their ideas for how waste can be minimized. Domestically, we can foster a culture in which everybody cares about maintaining the lowest level of waste. That way, we can collaborate on how to come up with new ways of improving our processes and streamlining our operations. If we train our team properly, all of us can help avoid waste and save money while producing high quality product.

Table of Contents

- Effective Startup Practices to Minimize Waste in PET Blowing Production

- Collaborative Strategies for Reducing Waste in Blow Molding Operations

- What Are the Common Causes of Waste in Blow Molding Production?

- Reducing Waste to Reduce Cost of Goods in PET Blow Molding

- How To Educate Your Team On Waste Reduction Practices In Blow Molding?